All Products are in stock

and shipped from France.

Delivery within 48 hours.

and shipped from France.

Delivery within 48 hours.

Our categories

-

Special effect paints

- Chameleon effect paints

- Paint with an opalescent pearlescent sheen

- Prismatic Paints

- Candy Paints

- The fluorescent paints

- Phosphorescent paints

- Fluorescent paints UV

- Crystal Pearlescent Clearcoat

- Marble and crystal paint

- Paints that react to temperature

- Paints that react to light

- Magnetic paint and rust color

- Chrome effects

-

Our paint ranges for bodywork

-

PAINT KIT FOR CAR BODYWORK

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

- Primers for car paints

- Epoxy-polyester paint for wheel rim

- Spraypaint bodywork

- Metallic effect paints for car bodywork

- Tuning paints with effects

- Pearlescent paints for bodywork

- Solvent-based 1K base coats for cars

- 2K paints for cars

- Vintage cars paints

- Rustproof car frame paints

- Car underbodies and pick-up trucks paints

- Car cylinder block paints

- Dashboard paints

- Car brake paints

- Plastic bumper paints

- Car wing mirror paints

-

CAR COLOUR CODE

-

PAINT KIT FOR MOTORCYCLE BODYWORK

-

Motorcycle and scooter paint code - Can or spray paint

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

- Motorcycle tuning paints

- Motorcycle paint primers

- Motorcycle spray paints

- Epoxy paints for motorcycle frames

- Epoxy paints for motorcycle rims

- Metallic motorcycle paints

- Pearly motorcycle paints

- Motorcycle clearcoats

- The paints for plastic of cross country motorcycle

- Jet ski hull paints

- Paints for Quad

-

Motorcycle and scooter paint code - Can or spray paint

- Scooter fairing paints

- Helmet paints

- Auxiliary products

- Bicycle paints - Stardust Bike

- RAL Paint - Pantone Code

-

PAINT KIT FOR CAR BODYWORK

- Finish paints and topcoats

-

Artistic and custom specialties

- EPOXY RESINS

- Gilding with a gold leaf

- Pinstriping paint and brushes

- Hydrographic Film

- Covering car and motorcycle

- Pearls and Flakes bodywork

- Painting over the body

- Paint for fishing decoys

- Paints for guitars

- HIKARI : paints for models and miniatures

- Acrylic 3D Printing Paint – Primers, Colors, and Clearcoat

-

Bodywork accessories and consumables

- HVLP Spray Guns for car and motorcycle paints

- Our ranges of airbrushes

- Compressed air connections

- BODYWORK ACCESSORIES

- Abrasives for bodywork

- Buffing and polishing of bodywork

- Protective Equipment for painters

- POSTERS

- Paint air filters

- sample supports for paint tests

- Infrared and ultraviolet drying lamps for paint

- Bodywork adhesives and paint

- Air compressors for painting

- Paints for airbrush

Ceramic 2K car clearcoat Cerastar

New product

Ceramic clearcoat in pot or aerosol.

4 versions : Ultra high strength

CERAMIC NORMAL -S-N-F

CERAMIC X (extra hard)

Kits include varnish, hardener and thinner.

Available in Aerosol 290ml.

Avaibility: IN STOCK

Best ceramic varnish for cars

The CERASTAR® automotive top coat is called 'ceramic top coat' : this particular product shows amazing abrasion resistance thanks to the use of nanoparticles in its composition.

CERASTAR® is a special and innovative clearcoat manufactured by STARDUSTCOLORS.

The offers of the ceramic clearcoat:

- Slow (L) / normal (N) / fast (R) versions

Slow (S) / Normal (N) / Fast (F) versions

Kit 1 Liter (0.5L clearcoat + 0.25L hardener + 0.25L thinner)

Kit 2 Liters (1L clearcoat + 0.5L hardener + 0.5L thinner)

Kit 9.5 Liters (5L clearcoat + 2.5L hardener + 2L thinner)

Aerosol 290ml (two-component)

-

Extra hard versions rigid (X)

Kit 1 Liter (0.5L Varnish + 0.5L Hardener H440)

Kit 2 Liters (1L Varnish + 1L Hardener H440)

Specifications :

The versions of the CERASTAR S-N-F ceramic coatings are adapted to the size of the project to be painted. They are very beautiful, thick and levelling, glossy and easy to paint.

Slow version S : recommended for complete cars, allowing a slow hardening and a nice "stretched" look.

Normal N version : allow moderate or rapid curing for motorcycles for example, or for colder temperature conditions.

|

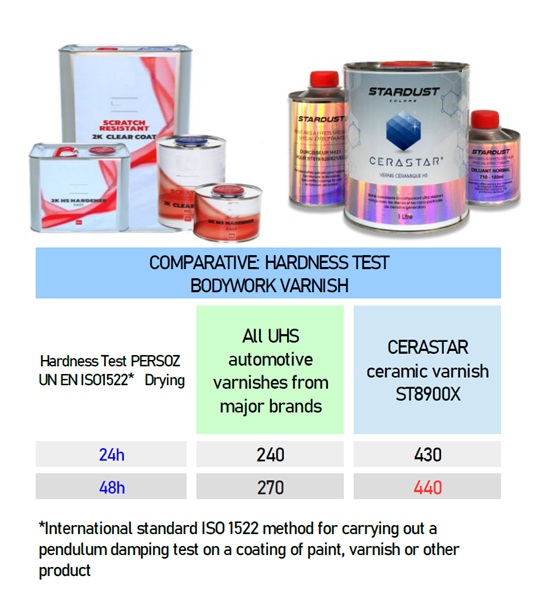

Hardness Measurement PERSOZ UN EN ISO1522 |

Hardness Measurement BUCCHOLZ* * |

|

After 24h : 268 / After 48h : 350 |

After 24h : 37 / 32 |

Ceramic varnish CERASTAR X (rigid) or F (flexible) has a higher level of hardness and dries very quickly.

Both versions are based on a different type of chemistry : these very fluid coatings become harder very quickly and form dry, glossy, ultra-hard layers.

They offer a higher level of resistance than all conventional bodywork varnishes.

|

Hardness Measurement PERSOZ UN EN ISO1522 |

Hardness Measurement BUCCHOLZ** |

|

After 24h : 438 / After 48h : 440 |

After 24h : 20 / 20 |

It is very easy to clean. It resists better than other HS or UHS varnishes, to micro scratches / scraping / mechanical friction and also to the aggression of various chemical agents.

The exceptional characteristics of CERASTAR® clearcoat:

This high quality top coat is designed for cars and motorbikes, is easy to apply, super hard, and provides maximum gloss finish. Industry and building companies also use it for pieces subjected to severe rubbing or often exposed to chemical products (detergents, petrol...)

We can note a resistance rate more than 40% higher than with standard top coats . Some car companies (luxury brands) have chosen this technology for the complete coating and outstanding protection of their latest models.

CERASTAR® ceramic top coat is completely compatible with waterborne or solvent based auto body paints. The hardener (included) allows it to whether being used for spot repairs or complete finishings.

|

VERSIONS S-N-F |

VERSION X |

|

Mixture 2 : 1 by weight 100 parts ST8800-S-N-F clearcoat + 50 parts hardener (H421 H422 H423*) Thinning : approx. 25% with thinner 712 |

Mixture 1 : 1 by weight 100 parts ST8900-X clearcoat + 100 parts hardener (H440*) 0 thinning |

|

Mixture pot life at 20°C |

|

|

30 – 120 min |

20 min |

*H421 slow / H422 normal / H423 fast / H440 special

Spray gun : Standard or HVLP 1,2 - 1,5 mm

Mode of application : Apply two coats with 10 minutes interval.

Drying :

|

VERSIONS S-N-F |

VERSION X |

|

Dry to the touch S: 60 min / N: 40 min / F: 30 min Commissioning S: 24 h / N: 20 h / F: 16 h Optimum hardness after 72 hours |

Dry to the touch 20 minutes. Commissioning 60 min Optimal hardness after 48 hours |

Volatile organic components:

Versions S-N-F : < 420g / L

Version X : 510g / L

Ceramic clearcoat for rims

The ST8900x ceramic clearcoat is extremely hard and dries very quickly (45 mins through)

The hardening of the varnish can be extremely rapid, so it is advisable, when painting complete cars, not to work at temperatures above 20 or 25°.

However, it is not a clearcoat that sticks directly to the metal.

It is possible to apply the ceramic clearcoat to a raw metal rim by applying, 2 minutes before, a coat of transparent primer for metals SILAX P760.

Discover the LinaQuartz® nano-ceramic liquid glass coating. This liquid product is not a varnish. it is applied in addition, above the glossy and dry clearcoat.

Can we sand or polish "ceramic" clearcoats?

Yes, in the same way as conventional body paint.

Please note that the X version cannot be polished.

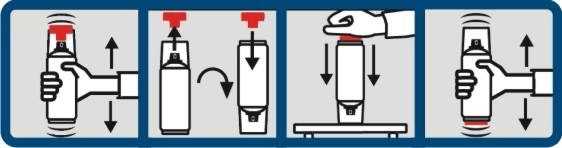

How to use spraycan :

Cerastar® is a registered trademark of StardustColors

* the Persoz hardness measures the resistance to scratching using a pendulum that scratches the surface. the greater the measurement, the greater the hardness.

**The Buccholz hardness measures the resistance to an impact by perforation. The closer the measurement is to 0, the greater the hardness.

Accessories

30 other products in the same category

WE ALSO RECOMMEND YOU

Recently Viewed

- Special Effect Paints

- Chrome Effect

-

Car and motorcycle paint

-

CAR COLOUR CODE

- AIXAM car paint

- ALFA ROMEO car paint

- ASTON MARTIN car paint

- AUDI car paint

- BMC car paint

- BMW car paint

- BUGATTI car paint

- CADILLAC car paint

- CHEVROLET car paint

- CHRYSLER car paint

- CITROEN car paint

- DACIA car paint

- DAEWOO car paint

- DAIHATSU car paint

- DODGE car paint

- FERRARI car paint

- FIAT car paint

- FORD car paint

- GENERAL MOTORS car paint

- HONDA car paint

- HYUNDAI car paint

- ISUZU car paint

- IVECO car paint

- JAGUAR car paint

- JEEP car paint

- KIA car paint

- LADA car paint

- LAMBORGHINI car paint

- LANCIA car paint

- LAND ROVER car paint

- LEXUS car paint

- Lotus car paint

- MASERATI car paint

- MAZDA car paint

- MERCEDES car paint

- MG car paint

- MINI car paint

- MITSUBISHI car paint

- NISSAN car paint

- OPEL car paint

- PEUGEOT car paint

- PORSCHE car paint

- RENAULT car paint

- Rolls Royce car paint

- ROVER car paint

- Saab car paint

- SEAT car paint

- SKODA car paint

- SMART car paint

- SSANGYONG car paint

- SUBARU car paint

- SUZUKI car paint

- TOYOTA car paint

- Volkswagen car paint

- VOLVO car paint

.

.

.

-

MOTO COLOUR CODE

- APRILIA motorcycle paint

- BENELLI motorcycle paint

- BIMOTA motorcycle paint

- BMW motorcycle paint

- Buell motorcycle paint

- CAGIVA motorcycle paint

- DERBI motorcycle paint

- DUCATI motorcycle paint

- GILERA motorcycle paint

- HARLEY-DAVIDSON motorcycle paint

- HONDA motorcycle paint

- HUSQVARNA motorcycle paint

- INDIAN MOTORCYCLE PAINT

- KAWASAKI motorcycle paint

- KTM motorcycle paint

- KYMCO motorcycle paint

- LAMBRETTA motorcycle paint

- MALAGUTI motorcycle paint

- MBK motorcycle paint

- MORINI motorcycle paint

- GUZZI motorcycle paint

- MV AGUSTA motorcycle paint

- PEUGEOT motorcycle and scooter paint

- PIAGGIO motorcycle paint

- SACHS motorcycle paint

- SUZUKI motorcycle paint

- SYM motorcycle paint

- TRIUMPH motorcycle paint

- YAMAHA motorcycle paint

.

.

-

CAR COLOUR CODE

- Finish Paints and Topcoats

-

Specialties

-

Accessories and consumables

.

.

- AIRBRUSH PAINT

- COLORCHART

COMMANDE

BLEU

En opaque :

Bleu cyan 1

Turquoise 2

En semi transparente :

Bleu phtallo 2

Bleu nuit 3

ROUGE

En opaque :

Rouge bordeaux 1

Rouge vif 3

En semi transparente :

Rouge cerise 3

NOIR opaque 3

NOIR Semi-transparant 3