The 3D printing process with FDM filament

In this series of articles dedicated to the discovery of 3D printing and paint for 3D printing, I present to you in this article one of the two main techniques most commonly used today both by the general public and by professionals.

FDM 3D printing is a material extrusion process! Filament is extruded through a heating head in which it will be taken to temperatures around 200°C in order to melt it. It then comes out through the nozzle of the heating head which deposits this melted filament on the printing plate. The filament placed on the plate will then harden using fans often integrated into the heating head. Generally, the filament is presented in the form of spools of wire with a diameter of 1.75mm as you can see in the image below:

The print head nozzle is like the tip of a pen, it is what will “draw” the shapes on the plate, but it is also what will determine the quality of your print. Just like the tip of a pencil, the finer the lead, the more precise we can be and draw fine lines and the larger the lead, the rougher our line will be!

The nozzle generally has an orifice of 0.4mm which allows layers of thickness up to 0.12mm to be produced. Thin layers give more precise and cleaner results but significantly increase printing time.

In order to produce 3D printing, the user must provide the printer with a specific file, often in “.GCODE” format. The printer will follow the digital instructions in the file to create the 3D object. Clearly, the file contains a “sliced” version of the 3D model. And in order to create these “sliced” files, we use software called a “Slicer”!

Slicer for FDM printer

There are many slicers out there and the choice comes down to individual preference! For my part, I only use “Ultimate Cura”, when it comes to FDM printers. It is a very powerful and very popular slicer which has the added advantage of being completely free.

It is in the slicer that everything will happen before being able to make a print. This is where you position your parts on the platen, but also where you adjust the size of your parts and where you define all your printing parameters (speed, quality, support, weight, etc.).

There are so many things to explore and you will have plenty of time to discover it for yourself! Just keep in mind that the slicer is an essential tool for 3D printing (no slicer = no print).

Well, now that you know how an FDM printer works and how a print file is prepared, let's now see what it is possible to do in FDM!

Possible applications of FDM printing

The applications are very numerous: figurines, cosplay, jewelry, mechanical parts, various accessories, games, toys, etc. And the list is long ! However, some applications are more suitable than others and here are the main ones that I have selected: Cosplay/accessories, mechanical parts, toys, 1/1 size figurines.

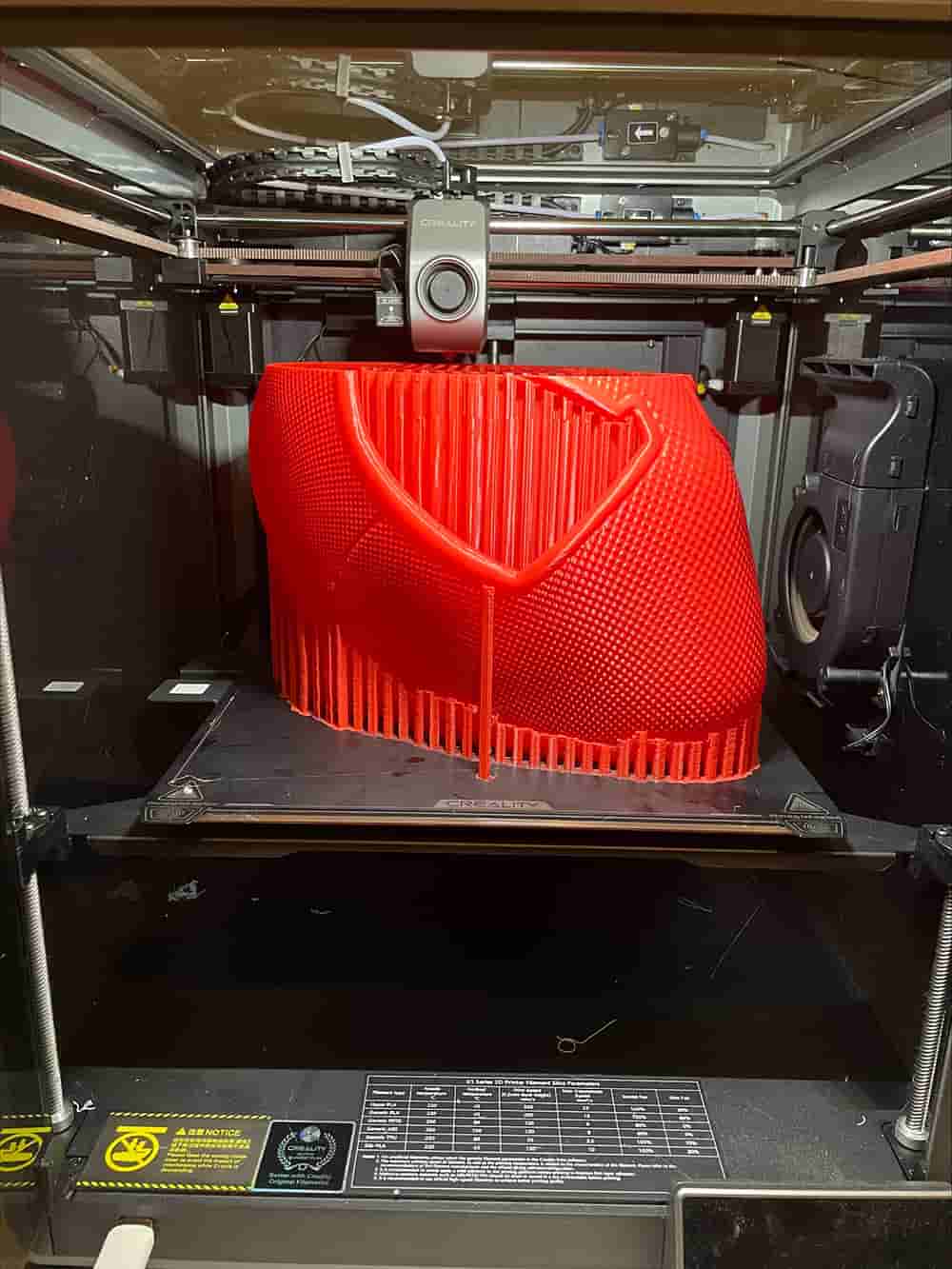

COSPLAY by Printing with filament - FDM

Personally, when I think of FDM printing, the first thing that comes to mind is cosplay designs! This is one of the most common applications! FDM printers offer a large printing volume, which makes it easier to produce large parts. In addition to that, the PLA plastic filament has good mechanical resistance and the printed object will largely resist small shocks that it may receive while being transported or worn. This is why we now find many people making their armor (example: Iron Man) or their accessories (sabre, pistol, helmets, etc.) using FDM 3D printing. Below is an example of a cosplay made in FDM 3D printing:

FDM prints of mechanical parts/accessories

This is a second very common application, many people use their 3D printer to make “mechanical” parts and “accessories”:

This could be wall shelves, plastic spare parts on a motorcycle/car, a telephone holder, or even a piggy bank... In short, all objects that can be used to improve our daily lives! Once again, for the resistance of plastic, its low cost and simplicity compared to resin printers, we very often favor FDM printers to create this type of object!

3D FDM prints of toys or figurines

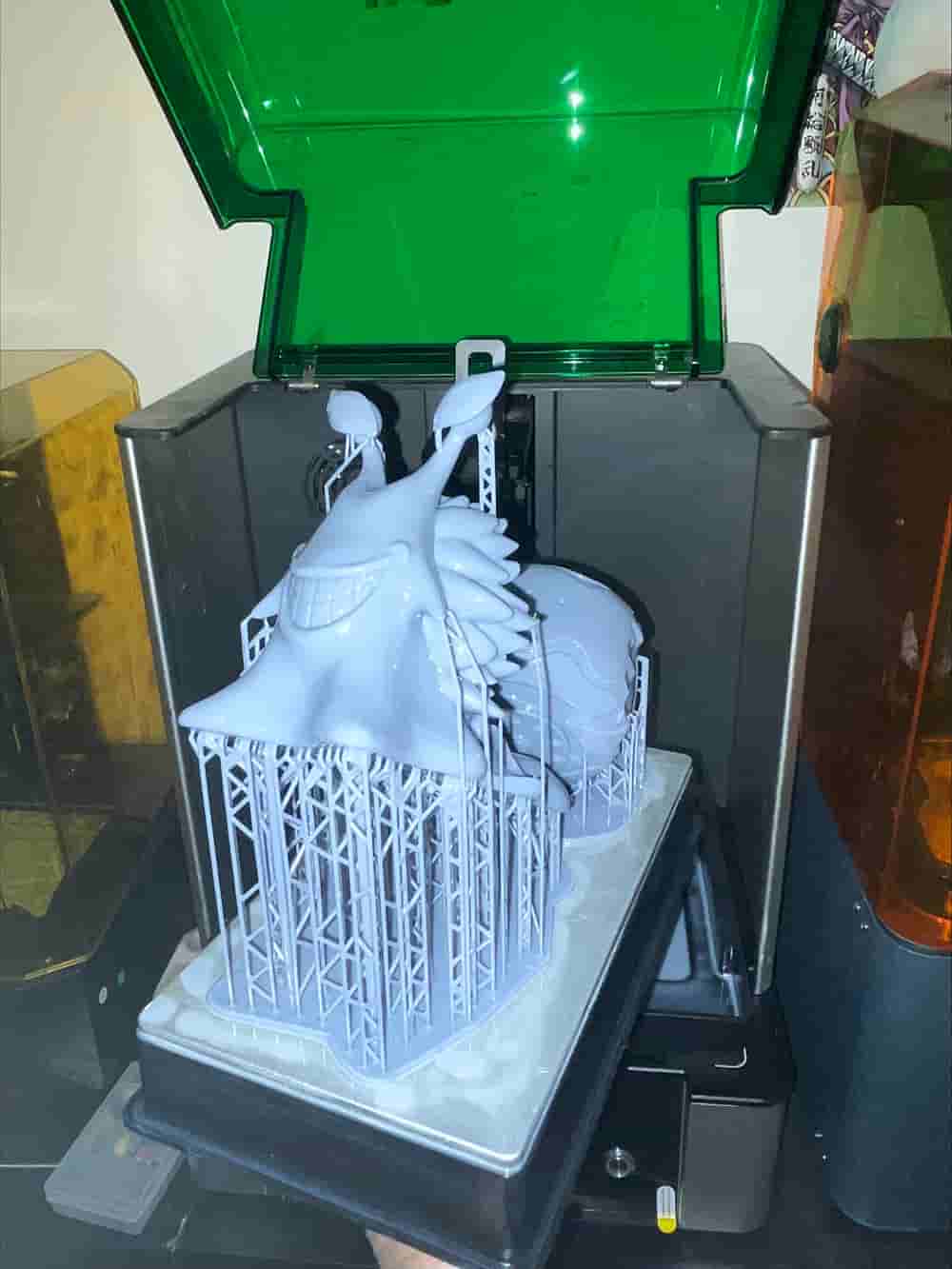

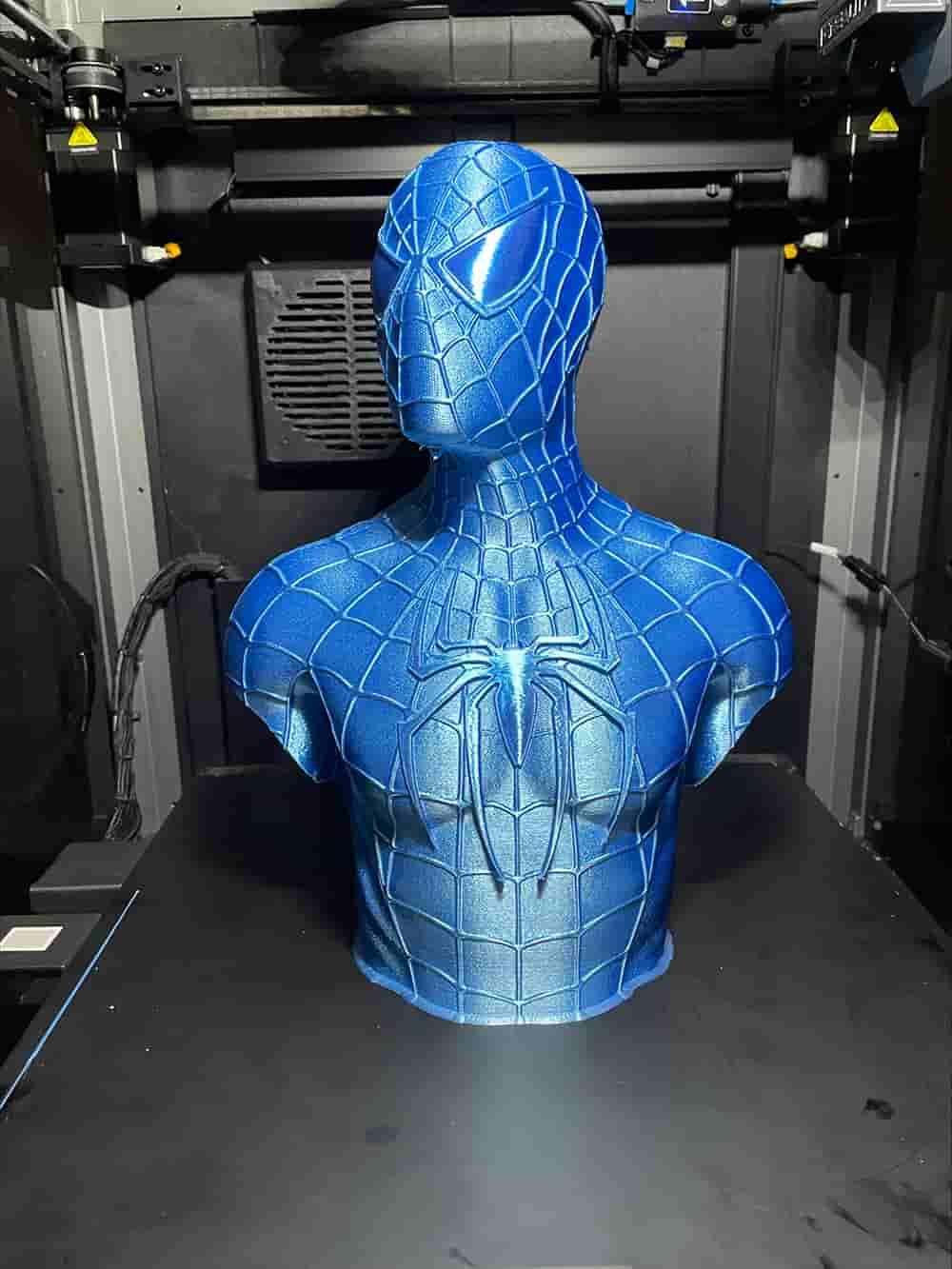

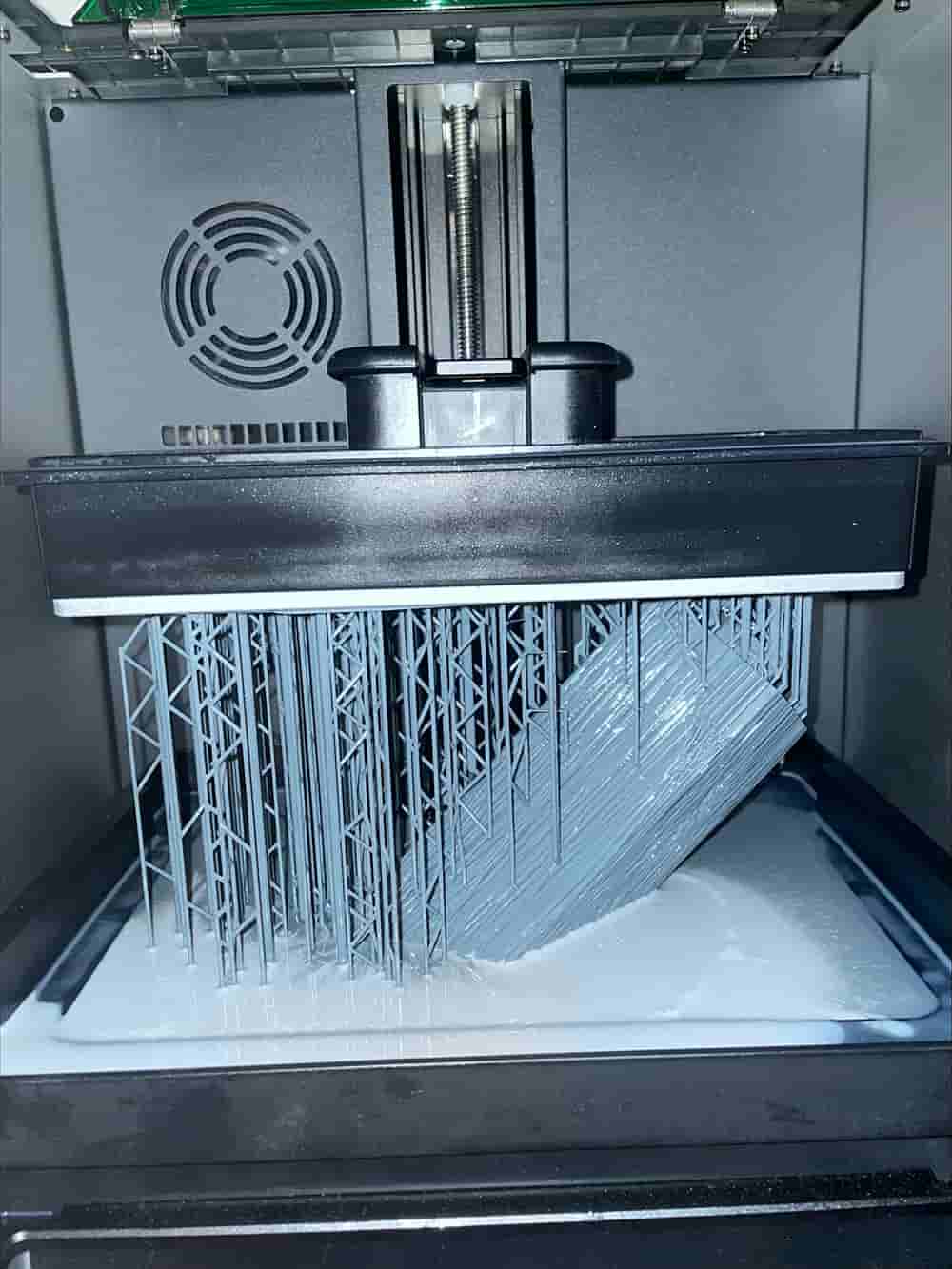

The last application of FDM printing that I wanted to mention is the manufacturing of figurines or articulated toys. Many people use 3D printing to make figurines. Even if FDM printing is not the most suitable for doing this, there are certain cases where it lends itself quite well. To make figurines without too much detail like Pokemon for example or very large figurines in 1/2 or even 1/1. Making the figurines in very large sizes allows you to have large blocks which will later be easier to sand in order to make the surface smooth and erase the print streaks. However, we can make smaller figurines with the wide range of filament colors and have some pretty cool pieces!

Here are some examples :

There you go, I think you know everything there is to know about the basics of FDM 3D printing. You now know how it works, how to start printing and what can be achieved. Of course, there are still a lot of points to discuss but the goal here is to present the main points in order to have the basic notions!

Painting on a resin 3D print

FDM VS Resin, which paint for 3D figurine to choose?

Which painting for 3D print?

How to paint 3D prints?

Choosing acrylic paints for 3D printing