Aluminum in the form of pigments

Aluminum in the form of pigments

Our series of articles focuses on the properties, differences and composition of pigments for car paint, motorcycle paint and bike paint. For example, mother-of-pearl, glitter, organic and inorganic pigments and of course the king pigments, i.e. aluminum pigments.

While not the finest grades of pigments, they are undoubtedly the most widely used pigments and qualities most valued by automotive color and paint designers . Indeed, the aluminum pigment offers a series of advantages and incomparable technical quality. Its only rival is mother-of-pearl pigment, which differs in a few aspects, such as its colors, refined effects and transparency.

The aluminum pigment is used in the composition of most metallic automotive paints. It has become indispensable thanks to its remarkable quality, first of all its opacity, coverage and its very effective visual effect of metallization.

And these are not all the qualities that it allows, because we must not forget its extremely low price which allows it to be placed in the first position of pigments in the value for money. It is also a pigment totally resistant to sunlight and very little subject to oxidation. What more could you ask for ?

Manufacture and types of aluminum pigments

Mainly used in the field of automobile construction, but also in architectural fields, this extremely fine, opaque, light and economical metallic pigment has been used for around fifty years.

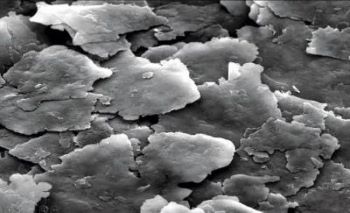

Very present on earth, this non-ferrous metal is abundant and easy to transform. The manufacture of this pigment, which looks like a kind of Corn-flakes if observed through a microscope, is now well mastered and pigment manufacturers have become such experts that they can now decline it in all kinds of shapes, sizes and effects for these metallic glitter microphones.

The manufacture of an aluminum pigment begins with the creation of a thin layer of aluminum, produced by electrical deposition on a support. This large sheet of aluminium, the thickness of which does not exceed a few microns, is then split up and reduced to very fine particles.

These aluminum pigments are then sieved into different sizes depending on the manufacturing purpose. After filtering the different sizes, the pigments are classified into different ranges and will be used to create different painting effects. These aluminum pigments can undergo other treatments, to obtain specific characteristics.

Special aluminum-based pigments

Special aluminum-based pigments

Some of these pigments are coated with silica at a microscopic level and this allows them to resist oxidation by water. Thus, these pigments can be used in the preparation of water-based acrylic paint.

Other pigments undergo a coating treatment which allows them to float, these pigments are then called "leafing" or floating, because they are able to position themselves on the surface of the paint, rather than inside the film of the paint.

There are also types of aluminum-based pigments, of very high quality and capable of creating or imitating mirror effects, thanks to the perfection of their structure and shape.

Delivery characteristics and specialties of aluminum pigments

Among the most extreme aluminum pigments in their technology, we find holographic pigments, which have wavy shapes and create quite extraordinary prismatic reflections. There are also aluminum pigments which achieve a very high level of transparency thanks to their extraordinary fineness.

Some of these pigments reach exorbitant prices, from 500 up to 1500 euros per kilo, while low aluminum pigments range cost from 10 euros.

The aluminum pigments can be delivered in different forms. Their raw, basic form is a very light and highly volatile powder. This form can pose some dangers, as it can be explosive. Often the pigments are wetted with 10% solvent, or directly dispersed in the form of liquid pastes, which are much easier to use.

Pigment paste for car paint

Candy ink for car paint

Mother-of-pearl pigment for car paint