NeoChrome paint in 400 ml Spray – anti-corrosion chrome effect

2 offers:

NeoChrome spray paint 400 ml

or

complete NeoChrome paint kit with Cerastar 8800 clearcoat in 2K spray for undercoat and clearcoat

Products in stock

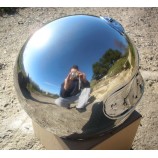

NeoChrome paint is a chrome effect based on rare metal forming a real mirror.

Compared to other types of chrome paints, it has many advantages

* it is anti-corrosion (it does not oxidise with humidity or over time)

* it creates an exceptional chrome mirror

* it is UV resistant and does not yellow over time

* it can be clearcoated without losing the mirror effect

Application field : rims, headlights, automotive accessories, architecture, decoration, all exterior applications

NeoChrome Spray offers

►NeoChrome paint in 400 ml aerosol*

► complete NeoChrome paint kit in 3 aerosols (2 ST8800 2K ceramic clearcoats + 1 NeoChrome)

Neochrome in pots is available on this page.

The black basecoat is not included in the kit

The silax fixative is not included in the kit

Coverage: 0.8m² max

Summary of the 3 or 4 steps* of the NeoChrome paint system SPRAY version:

1 ► Undercoat: ceramic clearcoat ST8800 (2K Spray) – Drying 3 days / 20°C

2 ► NeoChrome (1K Spray) – Drying 5 days / 20°C

3 ► Finish: ceramic clearcoat ST8800 (2K Spray) – Drying 1 day / 20°C

Respecting the drying times and instructions is very important to achieve the chrome effect.

A 4th step is possible between NeoChrome paint and the Clearcoat: the chrome paint can be coated with Silax fixative only 10 minutes after application (at 20°C) without waiting five days of drying and thus the finishing ceramic clearcoat can be applied immediately after the Silax.

Instructions for the NeoChrome spray paint system

Important: the recommended application temperature is 20°C. You must adjust your application technique depending on temperature: in hot temperature, drying times are shortened, while in cold temperature, drying times are longer.

The Base :

Any background colour is suitable, however we recommend application over a black base. This can be a raw surface, painted with a black paint or primed with a black primer when painting a raw, metallic or wooden substrate.

It is possible to use the specific black colour primer P714 for metal or aluminium when painting bare metal (all types)

The basecoat must in all cases be sound, dry, degreased, sanded with P500 and dust free.

► Step 1: Undercoat with ceramic clearcoat ST8800 2K

The glossy and hard undercoat is necessary to obtain a mirror effect. Application on ST8800 2K ceramic clearcoat in aerosol is recommended for best results.

It is possible to use for the base, a high quality 2K polyurethane gloss. Any other product will not achieve a mirror effect.

2K aerosol of ultra-hard clearcoat with hardener

Activate the hardener by pressing with the red button on the bottom of the aerosol. Shake well before use, wait five minutes then proceed with application.

Use the aerosol content within one hour.

Application in 1 or 2 glossy coats

Drying: 3 days at 20°C. Additional time is necessary if the temperature is colder (5-7 days). Likewise, at warmer temperature, drying time can be shortened to 2 days.

It is important to obtain a very hard and very glossy undercoat, otherwise the mirror effect will be of poor quality with a blurred finish.

► Step 2: NeoChrome

NeoChrome spray paint is applied with several very thin/quick passes*. It is important to spray thin or quick coats to allow proper metalisation formation. Avoid thick coats.

*When painting with a spray gun, very thin coats are applied. To obtain the same result with aerosols, you must spray coats in “quick” passes.

Several thin coats must be applied, it is not recommended to apply more than necessary, this can cause a darker chrome finish.

Respect sufficient evaporation intervals between each thin coat, and avoid applying a new coat if the previous coat has not yet evaporated.

NeoChrome paint evaporates between a few seconds and 1 minute depending on ambient temperature.

Drying: three possible options

1 ► 5 days at ambient temperature (20-25°C) then clearcoat, or

2 ► 2 to 3 hours in oven at 60 – 80°C then clearcoat, or

3 ► 10 minutes at ambient temperature (20-25°C) then apply SILAX fixative in aerosol (lien) then clearcoat

It is possible to combine several drying options.

If drying is not respected, the mirror effect may be reduced or annihilated.

► Step 3: Finish with ceramic clearcoat ST8800 2K

Application of the clearcoat provides protection against abrasion and weather.

NeoChrome paint is anti-corrosion and does not fear water or humidity, however it forms a metal film of a few microns, and can be fragile to rubbing.

Important tips:

-

Work at 20-25°C

-

Use a hot air source during application to aid evaporation in cold temperatures, and because an aerosol does not deliver air like a paint spray gun does

-

Temper aerosols before use. Do not use cold

Use of the 2K ceramic clearcoat aerosol with hardener

Activate the hardener by pressing with the red button at the bottom of the aerosol. Shake well before use, wait five minutes then proceed with the application.

Application in 2 glossy coats.

Use the aerosol content within one hour.

Drying: 24h at 20°C.

Ambient temperature*: the ambient air temperature must always be taken into account, but it is very important to check that the substrate and the liquid paint are at the same temperature.

The following recommendations apply to both NeoChrome paint and varnish:

The ambient temperature during application plays a decisive role. A range of 20 to 25 °C is ideal for achieving the best results.

When the temperature is low, the evaporation of solvents and the hardening of layers become slower, and the viscosity of the products increases, making them more difficult to apply. It is therefore important to avoid working on parts that are too cold: it is advisable to bring the substrates and components to the correct temperature before painting. Similarly, the products themselves should not be used when cold: it is best to bring them to room temperature, including aerosols, to ensure correct and even spraying.

NeoChrome for headlight reflectors

NeoChrome paint can be used for headlight reflectors because it has very high reflective properties.

It is applied to the reflectors by first applying the ceramic varnish and allowing it to cure thoroughly.

Then, NeoChrome paint is applied.

In the case of headlights, i.e. headlight reflectors protected by a lens, NeoChrome paint does not need to be covered with a varnish. Its anti-corrosion properties are sufficient to ensure the paint's long-term durability.

Questions and Answers?

►I applied a black base coat with ST8800 ceramic varnish and left it to dry for four days. Is that sufficient?

A minimum drying time of seven days is recommended, especially in cold temperatures. As a precaution, it is possible to extend the drying period to 14 days. The quality of the chrome effect depends on the hardness and gloss of the base coat; longer curing time gives better results.

?► After the ST8800 varnish has dried, should I degrease the part or just blow it dry and apply the chrome? What degreaser should I use?

It is not advisable to use degreasing solvents, as these can leave marks. If the item has become dirty, a water-based cleaner can be used, such as washing-up liquid, followed by rinsing with water. This is an exception, as we generally recommend dry cleaning, simply removing dust very carefully with a microfibre cloth or even cotton wool.

?► After applying the chrome, I left it to dry for 10 to 15 minutes, then applied a very thin layer of Silax, which gave it a petrol colour. I find that it is less shiny when I apply the varnish.

It is normal for there to be "oil stain" colour effects (see video).

If there is a reduction in the mirror effect, there are several possible causes:

This may be related to the lack of shine in the Silax layer, and therefore after gloss varnishing and complete hardening, the full mirror effect will be visible.

Silax must be applied in two thin coats. Applying thick coats can affect the mirror effect.

The chrome paint was not dry enough and/or the temperature was too low.

? ► Should chrome be left to dry longer before applying Silax?

Normally, 10 minutes is sufficient at a temperature of 20°C. Of course, the longer it dries, the less risk there is of damaging the mirror effect, and therefore the greater the chance of maintaining maximum mirror effect.

? ► I would like a ceramic varnish that dries faster, if possible.

For this, you need to use the spray version, which dries and hardens much faster (24 hours).