Nano Ceramic permanent protective coating LiNaQuartz® 9H

Linaquartz is a real glass barrier, in the form of a concentrated liquid which when dry creates a layer of micro quartz with thickness below 1µm (hardness up to 9H)

4 offers:

62ml bottle

complete kit

1L

5L

In stock

Delivery within 48h

Instructions for use, Data sheet and Safety data sheet

LiNaQuartz®, nano-ceramic protection

- Permanent protection for bodywork against scratches and shocks

- “3D Effect” Ultra Gloss

- Hydrophobic

- Anti-corrosion and anti-oxidation barrier

- UV and weather resistant

- Resistance up to 1000 °C

- Chemical resistant

Presentation

LiNaQuartz® is a StardustColors brand and is the acronym for Liquid Nano Quartz.

LiNaQuartz 9H is derived from a new resin family (based on NITROGEN-SILICON nano-elements). LiNaQuartz is a Nano Quartz permanent protection, a variant of nano-ceramic coatings, extra fine and extra hard (9H represents the highest degree of hardness for the pencil hardness test used to evaluate the scratch resistance of a coating's surface). The product comes in the form of a clear and concentrated liquid, which hardens quickly while evaporating (using heat, air and moisture) and turns into a real gloss and hard quartz type glass film (SiO2 silicon dioxide) less than 1 micron (0.001mm) thick.

Extreme resistance

Linaquartz is the ultimate coating for the requirements of the highest level at an affordable price.

It forms a durable and permanent barrier for years:

Linaquartz is easy to apply over all topcoated bodyworks, bumpers, headlights, rims, plastics and glasses, and protects against scratches, gravel projections, sun, corrosion, salt and dirt. It creates a lasting deep gloss, a true ice effect. Linaquartz is also remarkable by its hydrophobic effect, and its resistance to chemicals, UVs, heat (1000 °C) and abrasion

Multi-layer:

The unique formulation of Linaquartz 9H allows it to be applied in several layers, making it possible to form a thicker and harder film and achieve higher scratch and impact resistance.

Adhesion:

Linaquartz creates a permanent link with the surface: non-detachable, it does not come out in the wash, and cannot crack or tear.

The offer (complet kit) includes:

62ml Linaquartz 9H

2 microfiber cloths

20 Cotton clothes

1 applicator pad

Nitrile gloves

Quick application guide

WARNING!

Ensure you read the data sheet and safety instructions before using this product. Strictly adhere to the safety instructions (SDS available on the site)

LINAQUARTZ® 9H requires cleanliness and care. It is necessary to wear personal protective equipment. Use a respirator mask and the gloves included in the kit. The LINAQUARTZ® 9H container should be warmed to room temperature before opening to prevent the condensation of moisture in the product. Open the bottle gently and gradually to release the gas pressure. Do not mix! LINAQUARTZ® 9H reacts strongly with water, alcohols and solvents! Flammable product and vapors.

SHELF LIFE

6 months from the date of delivery at 10 °C. Keep in a cool (10°C), dry, and dark place. A reaction between LINAQUARTZ® and moisture can be slow, and can lead to an increased viscosity, making the product unsuitable for the purpose for which it was designed.

PRODUCT APPLICATION

LINAQUARTZ® 9H is a ready-to-use formula that is easily applied over all topcoated bodyworks in good condition. The bodywork must be prepared, cleaned, free of dust, dirt or grease, and if possible buffed. The surface must be completely dry. Apply the product in a closed and sheltered environment. Before applying LinaQuartz, clean the surface with the Cleaner which will increase the product adhesion and ensure the absence of dirt. Shake the product.

1/ Cover the applicator pad with a microfiber wipe and add 20 to 30 drops. Apply the product to a section of 1m² maximum, without forcing, by crossing horizontally then vertically. (Use an applicator cloth for up to 2 sections)

2/ Wait for 10 seconds to 4 minutes (depending on temperature and humidity conditions). A liquid separation at the surface, or a multicolored "oil effect" can be observed when it's ready to be wiped. Do not wait more than 3 to 5 minutes before wiping! If the product cannot be easily wiped or if you notice streaks when wiping this indicates that you have been waiting for too long.

3/ Use the microfiber cloth to wipe the surface in a circular motion for leveling and removing the excess product. Apply a very, very light pressure, just enough to keep the microfiber cloth under your hand. The microfiber cloth can be folded in 4. Thus 8 new faces can be created. After a first quick wipe, fold the microfiber cloth to obtain a new face, and again, wipe gently and only with very light pressure applied.

Once wiped, and after a 5 min delay, do not wipe an area that has been previously wiped! This would affect the gloss and make marks! The "melt" with the microfiber between the limit of each section (for example: middle of the hood) is done for 10 minutes maximum. A layer of LinaQuartz is enough to obtain a high protection. If you want to apply a second layer, it has to be done between 20 and 40 minutes after the first layer (too early it can remove the product, too late it will not adhere). The application on the whole vehicle can be accomplished in less than one hour.

DRYING

Dry to the touch: 2-4 hours/Through-drying: 24h-48h/Maximum hardness: after 3 to 7 days.

Do not wet, expose to moisture, or touch the treated surface during the next 48 hours.

Do not wash for 7 days after application

WASTE

The liquid waste from LINAQUARTZ® should not be mixed with other solid or liquid waste. The waste from LINAQUARTZ® must be collected separately in dry containers and returned to waste disposal centre.

LINAQUARTZ 9H, NANO-CERAMIC COATING: DETAILED APPLICATION GUIDE

The application of our nano quartz coating is very simple and does not require any paint spray gun (It is nevertheless possible to use a spray gun)

All the following necessary equipment is provided in the kit:

A foam applicator pad and

microfiber cloths

A. Preparation of the substrate

One of the critical success factors for application and, most important of all, for a perfect adhesion of the product LinaQuartz, is the cleanliness of the substrate:

the background must be very clean, which means perfectly healthy (dusted, decontaminated*, free of silicone, degreased) and dry. In the case of a car body, the substrate cleaning may be conducted in a single stage or in several stages (these steps are not mandatory, however the more steps you complete, the better the adhesion and the quality of the application.)

1/ The cleaning

Conduct a thorough soaping/washing of the surfaces to be treated to remove dirt.

To ensure a deeper cleaning, you can use the claybar with some water: it will really decontaminate the embedded dirt from the topcoat pores.

Use our cleaner to dissolve dirt and grease

2/ Surface inspection

The nano quartz protection is recommended on new or in good condition surfaces.

On a car body, all existing imperfections, dust, "orange peel", scratches, will be like frozen in the glass layer, after application of the LinaQuartz coating.

If it is considered that the vehicle paint is in good condition, that its gloss is good, then you can go straight to step 4 of degreasing. If, on the other hand, it has defects, it is recommended to correct them before applying LiNaQuartz:

It is therefore important to inspect the bodywork carefully, using a lamp if necessary.

3/ Correcting the paint by polishing (Optional):

If you have orange peel or other important defects, and to ensure a perfect glazing, you will have to use the polished-gloss technique.

If the existing topcoat is glossy and in good condition, you can just polish it with a polisher + black foam and our Polarshine 10 polishing cream, without forcing, at 1000-1500 rpm. All polishing or buffing should only be done after a good cleaning of the bodywork, otherwise you polish the dirt!

After polishing and buffing, use a clean microfiber cloth to wipe the surface and collect residue.

4/ Degreasing

Apply the 'Cleaner’ degreasing solution, spraying it generously on a clean microfiber cloth and wipe the bodywork surface. The cleaner leaves the surface completely healthy and degreased, free of any dirt residue or polishing products. Allow the bodywork to dry, to ensure that it is perfectly free of moisture.

Do not mix and use microfiber cleaning cloths with those of LinaQuartz application!

On a clean surface, LinaQuartz creates a very strong adhesion, called covalent* (bond between the surface atoms and the product)

B. Application of the LiNaQuartz nano-ceramic coating

Always read the safety instructions applicable to the product.

Apply the product in a closed and sheltered environment.

Shake the bottle well.

Cover the applicator pad with an applicator cloth and apply a generous amount (30 drops for 1sqm)

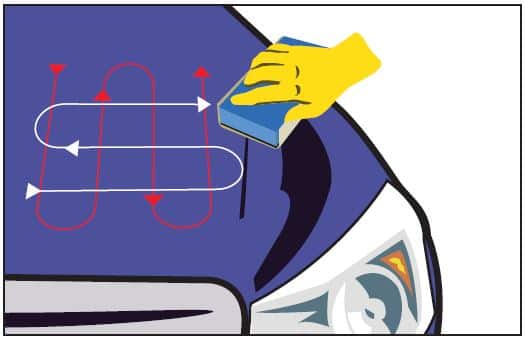

1/ Application

Apply LinaQuartz in passes, crisscrossing the surface, from left to right, then from bottom to top, without forcing on the applicator, use only the weight of the hand.

Proceed section by section, from 0.7 to 1 m² max (for example: half hood, 1 wing, 1 door, etc.)

Slightly overlap sections applied between them.

After applying the product in crossed layers, avoid touching anymore. Do not apply another layer after crossing the passes. Do not touch the surface with your fingers

2/ Flash time, evaporation and wiping

The product will "flash". It will quickly evaporate and the wet appearance will disappear by evaporation. A liquid separation at the surface can be observed, or a "petrol rainbow effect" starts to appear, when it is ready to be wiped. Do not wait more than 2 to 5 minutes before wiping! Note: on matt surfaces or when you want to reduce the gloss, wipe immediately without waiting.

You have to pay close attention to that. Depending on the climate, humidity and temperature, the product has a "Flash time" of 1 to 5 minutes

Pursue the application of the second section while the first one is flashing.

3/ Wiping

Do not wipe with the cloth that has been used for the application! Use a clean microfiber. The microfiber cloth can be folded in 4. Thus you can obtain 8 faces.

Wipe the first section with a clean microfiber cloth by a circular motion to level and remove the excess product, and only very, very light pressure applied (just enough to keep the microfiber cloth under your hand), until the surface is uniform. You have to ensure to remove any excess and check that there is no surplus, especially on the edges.

Fold the microfiber cloth to obtain a new face, and again, wipe gently and only with very light pressure applied.

After leveling, as soon as the drying starts, you absolutely must not touch the surface! If you touch or wipe the product after it begins to dry, there is a risk of scratching or matifying the product. Wiping between each section to “merge” the sections together is possible no longer than 10 minutes maximum after application.

Linaquartz forms a quartz type glass film, ultra fine, smooth and glossy, to prevent the formation of dirt and dust. It is abrasion resistant, water repellent, and protects from UVs rays and temperature.

Multi-layer:

Naturally, an even higher level of protection and durability can be achieved by applying multiple layers!

To apply a second layer, you will have to wait 20 to 40 minutes (depending on the climate, air temperature and humidity) after the first layer because if you apply too early the second layer, you will remove the first one. If you apply too late, it will not adhere

4/ Drying:

The drying of LinaQuartz is mainly activated by the air humidity, and also the heat

Dry to the touch: 2-4 hours/Through-drying: 24h-48h. Maximum hardness: after 3 to 7 days. To speed up drying, it is possible to bake or use infrared (120-130 °C for 20 min). Do not wet, expose to moisture, or touch the treated surface during the next 48 hours.

Do not wash for 7 days after application

Consumption

4ml/m², or for a 62ml bottle = 15m² per coat (a large complete vehicle)

Secondary uses

To be applied over headlight plastic, chrome, bumper plastic and rims. Always be sure to wipe away the excess on the edges and bodywork.

LiNaQuartz has numerous uses such as on vehicles, including effectively protecting all types of bodywork surfaces against gravel projections, corrosion, salt, dirt and oxidation.

LinaQuartz adheres to all substrates, even on glass: radiator grille, rims, fine chromes, headlight plastic and glass, plastic parts, bumpers

Questions and answers :

Does Linaquartz adhere to chrome?

Yes, it strongly adheres directly to chrome and all types of bare metals.

Does Linaquartz withstand chemicals and acid?

Yes, Linaquartz has a very high resistance to solvents, detergents, acids and fuels.

Is Linaquartz durable?

Depending on the number of coats, it can last from 3 to 9 years

Does Linaquartz adhere to glass? Is it useful on glass?

Yes Linaquartz has very good adhesion to glass. It prevents dirt and moisture from accumulating on the glass, thanks to its hydrophobic properties. In addition, it makes cleaning easier.

How to remove Linaquartz?

Once dry and cured, the product can only be removed by sanding or sandblasting

Should I use the same applicator pad for all sections? Should I throw away the pads and microfiber cloths after use?

Pads should not be reused (after 10min), and cloths should not be used to wipe more than 2 consecutive sections, as they contain dried residues which could scratch or dirty the finish.

From how long after the application of a varnish freshly sprayed and dried at room temperature (not in an oven), can we apply Linaquartz?

It is best to wait a minimum of 4 days to a week before applying Linaquartz.

Ultimate protection for industry, architecture and decoration

Linaquartz show natural properties against graffiti and is highly hydrophobic. In addition, Linaquartz is easy to apply, protects against corrosion and adheres to almost any surface:

the cleaning costs are reduced, thanks to these combined effects: the surface coated with Linaquartz stays clean longer, because the dirt does not build up, and the water drops roll by without sticking to the surface.

The cost of maintenance is reduced, through superior corrosion protection that protects parts from damage and corrosion

There are countless application possibilities: tanks, wind turbines, facades, carpentry, etc.

Technical characteristics

Packaging: 62 ml

Application: bodywork and auto/moto parts

Durability: 3 years/150 washes (-20 °C/+ 40 °C, detergent Ph<12)

1 year/50 washes, extreme conditions -40 °C-55 °C, detergents Ph>12

Consumption: 4ml/m²

Thickness: <1µm

Hardness: 9H

Hydrophobic: 105° @20mL, acrylic

Temperature resistance up to 1000 °C

Chemical resistance: 1<Ph<12