Among other types of car paints Stardust offers a complete range of solvent-based car paints, including 1K basecoats.

What is a 1K basecoat ?

First of all, it is a one-component paint : no hardener is needed*.

It is a thin paint that dries at room temperature.

It is not a topcoat: the paint must be quickly varnished with a topcoat, which ensures the protection of the paint.

After drying, the dry film is matt, thin and flexible. It measures between 20 and 30 µm.

PAE / RFU : ready for use

Unlike polyurethane 2K paints, 1K paints can be applied directly and do not require a hardener.

Of course, they must be thinned — they are too thick in their pure state.

PAE is the name given to the diluted paint that is ready to be sprayed.

Mixing and thinning :

A bodywork thinner is used to extend the paint by 50% to 100%.

What are the advantages of a 1K basecoat ?

It is above all simple and easy to apply.

The product is fluid, extremely fine, and can be applied very nicely in thin layers.

It is difficult to obtain defects with this type of paint.

Drying takes place very quickly by evaporation, during which the paint levels out perfectly.

At normal temperature (20°C), you can apply several coats with an interval of no more than 1 minute.

The 1K basecoat does not require a hardener, so there is no issue with pot life or premature hardening.

Another advantage is the unlimited dilution a 1K basecoat allows: it can be thinned by 50%, 100% or more to obtain an ultra-fine product.

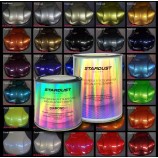

The characteristics of 1K basecoats are especially appreciated with metallic and pearlescent colours: the thinness of the dry film allows the pearl or aluminium flakes to lay perfectly flat on the surface, creating a smooth and flawless effect. In addition, the almost immediate drying time “freezes” the pearls or metal flakes in position. This prevents slippage, which can inevitably occur with slow-drying products like 2K paints.

Application of a 1K basecoat

The product must be varnished. Applying a 1K basecoat is a two-step process.

Covering time : this is an important point to respect if you want good cohesion and adhesion between the 1K basecoat and its topcoat. It is generally 30 minutes.

De-solvation time : this is the period after application which must be respected before overcoating (with a topcoat) to allow volatile solvents to evaporate. This time is generally 10 minutes.

The recommended application temperature is 15°C to 25°C.

Above this temperature, the curing and de-solvation times are shortened. Below, they are extended.

What happens if we can't respect the 30-minute varnishing window after application?

There will be greater surface tension on the paint. So, if you plan to apply stickers, make patterns or use stencils and adhesive masks, you must wait 1 hour, then sand lightly with P500 to allow the upper coats to adhere.

Hydro

On the website, we do not offer manufacturer colour formulas in a water-based automotive version.

However, we do offer a water-based binder to varnish, and a two-component water-based topcoat.

We can also create custom tints according to the main colour charts.

Hardening

Did you know it is possible to harden a one-component paint?

You can add 1% to 5% of any hardener to reinforce it.