Choose an option from the drop-down list :

- 1 single complete kit

- 1 single coloured complete kit

- 1 double complete kit

- 1 double coloured complete kit

- 1 single refill kit

- 1 double refill kit

The "Chrome At'Home" method gives the means to achieve easily and quickly chrome plating, in the garage or in the garden, without equipment or machine, on any type of support!

Professional systems are described on our website.

Chrome plating comprises several consecutive steps of spraying, and involves a non-hazardous chemical reaction (product not listed as carcinogenic, contains no heavy metals).

Can be implemented on any type of surface, once the substrate has been correctly prepared (cleaning, degreasing, sanding, applying an adhesion primer if necessary).

This first preparation of the part to be painted is done in accordance with painting's proper rules.

To ensure that the silver plating reaction is effective, it is necessary that the weather conditions best meet these guidelines: >20°C for the temperature of the ambient air in the workshop, for the temperature of the mixture (water + products) and for the surface of the structure to be chromed. If the temperature remains below 15°C, the reaction will be slowed down and will not give the desired results. The higher the temperature, the more satisfactory the results will be and the expenditure on products will decrease.

Installation:

- Demineralised water, 5 L or 10 L (available in supermarkets)

- Grate or holder

- Container for collecting liquids + empty bottle

- Kitchen scale for weighing

- Each bottle must be perfectly clean, with no residue. Do not contaminate the different liquids together.

- Prepare in advance all products thinned in bottles: the different phases must be carried out one after another, without interruption.

- Pressurise the 3 pump sprayers by pumping 60 times. Do not put too much liquid in the pumps: the more liquid is present, the less air to pressurise.

- Wear goggles during each step, and beware of accidental spraying in the eyes.

- Undercoat and final clearcoat applications should take place in a booth, in a well-ventilated area or outdoors.

Waste:

It is very important to collect waste water in a container. Dispose of waste material as hazardous products at the designated waste depot. Never discard waste into sewers. These products can pollute water and disrupt treatment plants.

Here are the detailed instructions:

VIDEOS on this page

- 1/ Apply 2K white undercoat:

Chrome At'Home Complete Kits include special aerosol undercoat.

Composition: Acrylic-Polyurethane 2K

You can also use any bodywork paint with hardener (2K finish, topcoated base ...)

Caution: Undercoat and final topcoat applications should take place in a booth, in a well-ventilated area or outdoors.

Harmful and flammable product. Follow the safety instructions.

Trigger the hardener at the bottom of the can by pressing several times. Then shake the can vigorously for 30 seconds. Aerosol service life: maximum 1 hour.

Application:

It is very important to obtain a very smooth and glossy paint.

Take the piece to be painted (clean and finely sanded), and spray a first very thin pass of paint to "create adherence".

After 2–5 minutes, apply the final pass, thick and very wet, to create a glossy surface.

Tip: If the coat is too thin, the paint will not be glossy. If the layer is too thick, you will get drips.

Drying: Leave the part to dry for 24–48 hours in a place protected from moisture, cold and dust.

After drying: Do not touch the part with fingers. It should not be sanded or degreased.

- 2/ Apply the wetting agent:

Non-hazardous product

Mixture: In a clean and empty spray bottle, mix 30–60g of concentrated wetting agent with 500g of demineralised water.

Installation: Place the part to be painted on a grate above the container. Spray all over the part including hidden recesses and leave for 10 seconds. Rinse with the pump sprayer filled with demineralised water.

Observe the surface: it must be completely wet and the water should not form beads. If dry zones appear, repeat the process and rinse again.

Go immediately to Phase 3.

Mixture service life: a few days

- 3/ Apply the activator:

Wear safety goggles. Product is irritating to the eyes.

Mixture: In a clean and empty spray bottle, mix 1.3ml (1.3g) of concentrated activator with 500g (500ml) of demineralised water.

Installation: Place the part on a grate above the container. Spray all over, including recesses, and leave for 5–10 seconds. Never let it dry.

Rinse twice with demineralised water. To prevent stains, any trace of activator must be removed before the next step.

Go immediately to Phase 4.

Mixture service life: 24 hours

- 4/ Spray the chrome:

Wear safety goggles. Product is irritating to the eyes. Wear protective gloves and clothing: the product can stain. Do not breathe vapours or wear a respirator: the final product contains less than 0.5% ammonia.

Mixing (2x 500 ml):

Solution A: In pump sprayer A: Add 250ml demineralised water, then 20ml A1 (ref CD2920, 20ml = 19.25g), then 10ml A2 (ref OX1910, 10ml = 12g), then top up with 250ml demineralised water.

Solution B: In pump sprayer B: Add 250ml demineralised water, then 10ml B1 (ref CD1900, 10ml = 12.2g), then 10ml B2 (ref RED5910, 10ml = 10.7g), then top up with 250ml demineralised water.

Installation: Place the part on a grate above the container. Spray simultaneously the 2 products over the part, always from bottom to top. The reaction occurs within 10–60 seconds. Keep spraying to ensure a good metallised coat. Then rinse and blow-dry.

Drying: 1.5h at 20°C or 40 minutes at 35°C.

Then go to Phase 5: clearcoating.

Mixture service life: a few days

- 5/ Apply the CAH 2K topcoat:

CAH 2K clearcoat is the only recommended product for direct adhesion on chrome plating and protection against yellowing.

Spray a first thin pass to "create adherence". After 2–5 minutes, apply a second pass to produce a glossy surface.

After drying, the clearcoat can be sanded lightly and an automotive topcoat can be applied over it.

Harmful and flammable products. Follow the safety instructions. Wear a respirator and work in a well-ventilated area.

Warning:

The chrome-plating process with sprayers is not suitable in the following cases:

Object size greater than 0.25m²

Object cannot be rinsed properly because of recesses or porosity

Any doubt? Send us a photo of your part by email at technique@stardustcolors.com

The Chrome At'Home offer is available in different versions.

To avoid streaks and marks:

The most important stage is the wetting phase: the part must be perfectly wet, no dry zones visible, otherwise the activator and the chrome will only settle on wet areas. To promote wetting:

Perform a quick flame treatment on the surface (with a gas flame)

Prepare wetting agent and activator 1–2 hours in advance

Use warm water at 30°C for mixing

Apply generously and rinse without insisting. Repeat if dry zones remain.

Apply the activator immediately after rinsing, and as quickly as possible over the entire surface.

Always spray chrome from bottom to top.

Avoid adhesives and masking tape.

Always rinse at each stage (except the wetting agent), especially in corners.

Do not attempt chroming parts larger than a helmet: the spray size does not allow it.

Kits*:

1/ CAH Single Kit, 0.75 m²

- 2 empty 500 ml spray bottles

- 3 empty 1000 ml pump sprayers with coloured rings.

- 1 spraycan of white undercoat (290 ml)

- 120 g of concentrated wetting agent

- 5 ml of concentrated activator

- concentrated solution A : 40 ml A1 + 20 ml A2

- concentrated solution B : 20 ml B1 + 20 ml B2

- 1 spraycan of topcoat CAH 2K 290 ml

- 1 pair of protective goggles

- 1 pair of blue nitrile gloves

- Instructions

- 3 pipettes and 3 graduated plastic beakers

2/ CAH-c Single Kit, coloured version, 0.75 m²

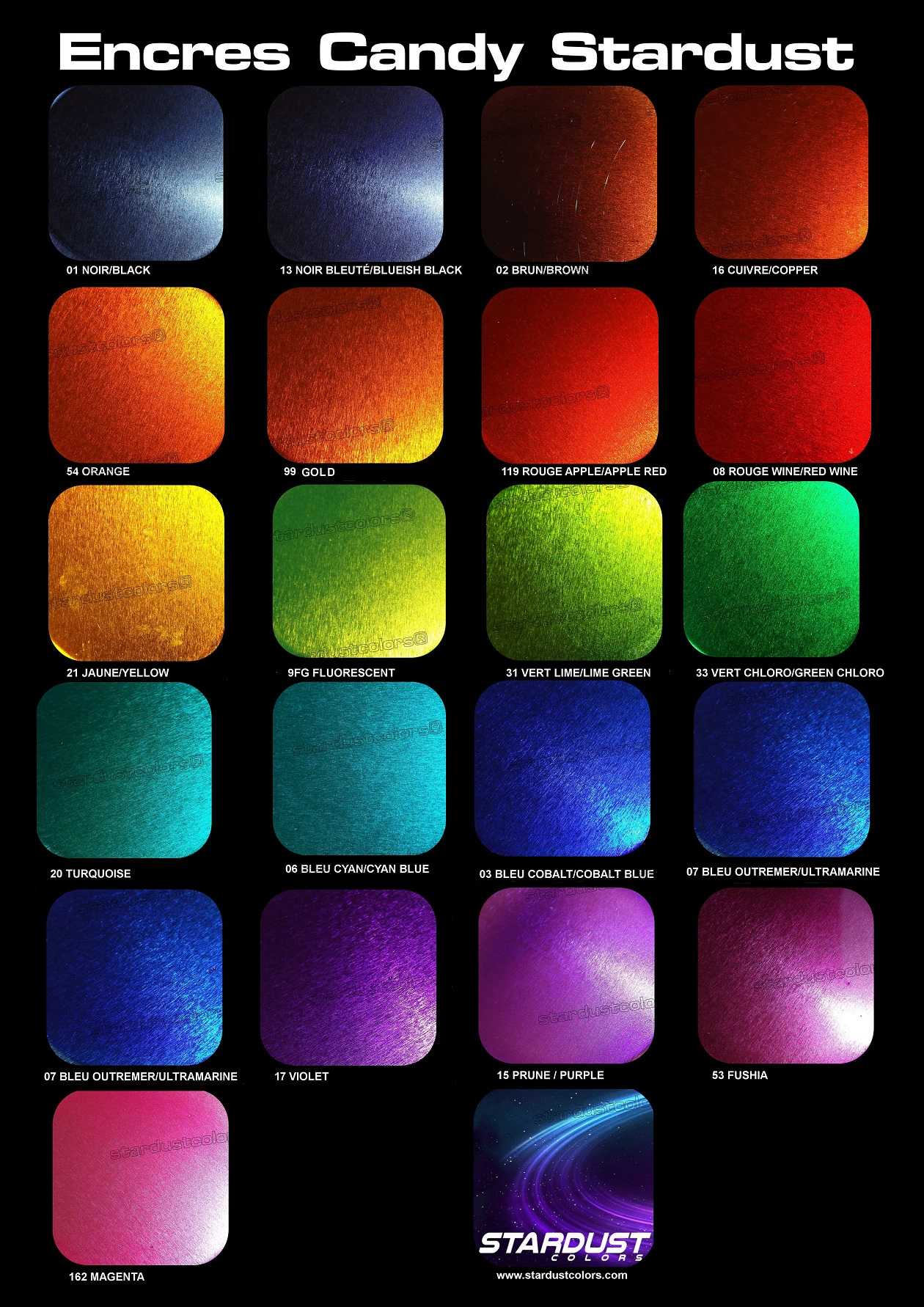

(Candy coloured clearcoat with a colour of your choice to be specified when ordering)

- 2 empty 500 ml spray bottles

- 3 empty 1000 ml pump sprayers with coloured rings.

- 1 spraycan of white undercoat (290 ml)

- 120 g of concentrated wetting agent

- 5 ml of concentrated activator

- concentrated solution A : 40 ml A1 + 20 ml A2

- concentrated solution B : 20 ml B1 + 20 ml B2

- 1 spraycan of Candy topcoat CAH 2K 290 ml

- 1 pair of protective goggles

- 1 pair of blue nitrile gloves

- Instructions

- 3 pipettes and 3 graduated plastic beakers

3/ CAH2 Double Kit, 1.5 m²

- 2 empty 500 ml spray bottles

- 3 empty 1000 ml pump sprayers with coloured rings.

- 1 spraycan of white undercoat (290 ml)

- 240 g of concentrated wetting agent

- 5 ml of concentrated activator

- concentrated solution A : 80 ml A1 + 40 ml A2

- concentrated solution B : 40 ml B1 + 40 ml B2

- 1 spraycan of topcoat CAH 2K 290 ml

- 1 pair of protective goggles

- 1 pair of blue nitrile gloves

- Instructions

- 3 pipettes and 3 graduated plastic beakers

4/ CAH2-c Double Kit, coloured, 1.5 m²

(Candy coloured clearcoat with a colour of your choice to be specified when ordering)

- 2 empty 500 ml spray bottles

- 3 empty 1000 ml pump sprayers with coloured rings.

- 1 spraycan of white undercoat (290 ml)

- 240 g of concentrated wetting agent

- 5 ml of concentrated activator

- concentrated solution A : 80 ml A1 + 40 ml A2

- concentrated solution B : 40 ml B1 + 40 ml B2

- 1 spraycan of Candy topcoat CAH 2K 290 ml

- 1 pair of protective goggles

- 1 pair of blue nitrile gloves

- Instructions

- 3 pipettes and 3 graduated plastic beakers

*Demineralised water not included

Refills:

Refill-1:

- 120 g of concentrated wetting agent

- 5 ml of concentrated activator

- concentrated solution A : 40 ml A1 + 20 ml A2

- concentrated solution B : 20 ml B1 + 20 ml B2

Refill-2:

- 240 g of concentrated wetting agent

- 5 ml of concentrated activator

- concentrated solution A : 80 ml A1 + 40 ml A2

- concentrated solution B : 40 ml B1 + 40 ml B2

For further information, contact us: info@stardustcolors.co.uk

Colouring:

Colour can be added using our coloured topcoats (included in the coloured versions). Available colours: purple, cobalt blue, cyan, chlorophyll green, lime green, gold, orange, red. Specify the desired colour in the comments box.

Performance and storage:

Return rates are approximate and depend on the number of passes applied. Water, part and air temperatures between 25°C and 45°C can improve efficiency and reduce product consumption.

Concentrated products can be stored for 3 months in the refrigerator, protected from light.

Waste:

It is very important to collect waste water in a container. Dispose of waste material as hazardous products at the designated waste depot. Never discard waste into sewers. These products can pollute water and disrupt treatment plants.

Precautions and safety:

Risk of explosion. Always keep concentrated solution A away from heat and light. Do not allow the product to evaporate completely and rinse the empty bottle.

Do not mix products A and B together. Follow the safety instructions and store out of the reach of children.

Safety Data Sheets: available upon request at infos@stardustcolors.com

Application Tips:

To avoid drips and stains:

· Always spray chrome from the bottom to the top

· Avoid adhesives and masking tape, as they absorb products and contaminate the reaction

· Always rinse at each stage (except the wetting agent), especially in corners. Also rinse supports and hooks

· Do not attempt to chrome parts larger than a helmet: the spray size does not allow it