Dispersants and anti-deposition additives for pigments and paints

Dispersants and anti-deposition additives for pigments and paints

For the manufacture of pigment-based paints, adjuvant additives are used to coat organic (colors) or inorganic (pearlescent, aluminum, fluorescent, metal oxide, etc.) pigments. These dispersant additives prevent the pigments from clumping together during the wetting phase and settling in the emulsion or the finished paint, forming a sedimented deposit, which is difficult to remix and keep in suspension.

For example, for the following mixture :

• Inorganic transparent base* PG17 (oxide green) 40% 80g

• Pigment PG17 60% 120g

A single transparent base is used to properly "wet" and disperse the inorganic pigments PG17. It works the same way for pigments like PR101 red, PR42 yellow oxide, pearlescent, phosphorescent and holographic, but also organic pigment. These have all different sizes and also different shapes. We must use a transparent base with different and personalized dispersions for each person, in particular according to their rate of absorption or "oil uptake".

Each organic pigment requires a custom transparent base, as its surface and size need a particular formula to “wet” it. If you try to disperse one with the inorganic base, the donuts don't come together well, the mixture spins too fast.

| Organic | 30.00% | Trans Base, Special | 70.00% |

The dispersant additive acts all around the pigment

Dispersion is done with high speed mixing (3500 revolutions per minute) using a serrated disc. The fine powder pigments (from 1 to 20µm) are added little by little to the transparent base composed of various additives, such as wetting agents, anti-foaming agents, surfactants and coating agents.

We use a disk with a diameter of 2/3 of the size of the pot, a propeller, or a flat disk for pigments based on aluminum or pearls to avoid damaging them.

| Serrated Cowl | Chinese Disc |

The dispersant additive will attach to the pigments and create filaments around it, like a barrier on a microscopic level, which will prevent the pigment from sticking or clumping with other pigments. Indeed, without the dispersant or anti-redeposition additive, the powders of micronized and finely ground pigments tend to stick together in a package once immersed in a liquid.

The dispersion process in a nutshell

The mixture must be done with the axis and the disc slightly off-axis, in relation to the center of the pot. The shaft must be immersed approximately 2/3 into the bottom of the mixture (i.e. towards the bottom of the tank). The pot or tub is preferably curved at the bottom. For solvent-based mixtures and dispersions, double-walled pots are used to avoid overheating.

Incorporate the pigment powder gently into the transparent base at 1200 revolutions/min (rpm). /p>

When the pigment has mixed well (1 min), increase to 3000 rpm (20 sec), then to 3500 rpm (for 30 minutes).

Scattering and Donuts

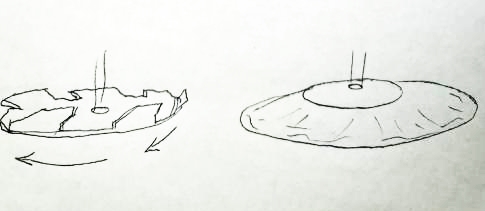

When mixing pigments to make a paint, the speed forms a sort of whirlwind. This aspect is a very important point in the success of the dispersion :

We must observe the appearance and appearance of the "Donuts" effect, it is essential :

The donuts must form after some time (example : 1 or 2 min), it takes the form of a rounded disc which allows the propeller or the disc to be seen.

It demonstrates a good rise in viscosity and good wetting of the pigments.

If the donut goes up and down and is not stable, then the height of the "cowl" disc must be adjusted, by lowering it or raising it.

If it doesn't form correctly, there will be a problem, the dispersion will not be done well, the pigment will not be properly wetted and coated.