The varnishing of a guitar

In our series of articles and tutorials on guitar painting, here is one of the most important topics, because it is that of finishing and protection: how to varnish a guitar.

6 steps to apply varnish to a guitar

Step 1 ► Prepare the support (depending on the different cases)

Step 2 ► Impregnate the wood

Step 3 ► Sand

Step 4 ► Apply varnish (different types and modes)

Step 5 ► Dry

Step 6 ► Polish

I invite you to find these steps with the complete and detailed instructions further down in the article, if you want to skip the general information.

I will also talk to you about the possibilities of adding a transparent tint to your varnish, and I will explain to you how to correct slight defects in the varnish.

Why varnish a guitar?

The varnish coats a guitar to protect it from all external aggressions, whether temperatures, humidity, scratches, dirt and all invisible dirt such as perspiration or grease. The varnish ensures effective protection of the wood of your guitar….

Particular care is dedicated to the finishing coat of musical instruments, which may be a lacquer or varnish. It is both a protective layer, a coat which gives the instrument a long lifespan, and it is also an aesthetic finish which adorns your instrument with a beautiful glossy layer, or sometimes even matte, depending on the tastes.

Certain varnishes are also believed to have natural acoustic qualities, because they allow better conduction of sound waves.

What varnish for a guitar

In this article, I will present to you here some solutions of products and methods for varnishing your guitar. From acrylic varnish, through nitro-cellulose varnish or 2-component polyurethane varnish, to epoxy glazing resin.

The woods that generally make up guitars, from the head, body or neck, are spruce, cedar, mahogany, rosewood, oak, maple. Most varnishes go well with the woods that make up the living instruments that are guitars.

You can choose according to your taste, according to the tools you have, and according to the possibilities offered by your workshop, solvent-free acrylic varnishes, single-component or two-component solvent-based varnishes, and I will also present to you an original solution with the resin glaze epoxy.

Are nitrocellulose varnishes really the best ones? Is this really a reality or a belief?

“Personally I only work at P.U. In my opinion, nitrocelluloses belong to the past, and I think that they have a hard life because of their desire to stick to what made the guitar famous: Fender and Gibson.

At the time polyurethanes were not yet well developed, and even though PU already existed, these iconic brands first used nitro. I had another one in my hands recently, a 95 Gibson whose varnish was a horror due to nitro which aged badly…

I think we still use and recommend nitro out of conservatism, or even snobbery. Afterwards it can be interesting for those who restore instruments to the original. It is also believed to have better acoustic quality, being more flexible it would let the instrument vibrate more than a P.U., for me this is quite ridiculous on an electric instrument.

And even on an acoustic, if a P.U varnish is well made it doesn’t muffle absolutely anything since it is only around 0.05 mm. »

Methods of applying varnish to guitar bodies

Varnish is a transparent, sometimes tinted, usually glossy layer composed of resins and polymers. Throughout the ages, different varnishes, different resin formulas, and different methods of application have been developed.

Glossy varnish enhances the texture, veins and grain of the wood, as well as its natural color, making it deeper.

The varnish is the most important step because it is the final touch. This is a delicate technique, because a varnish must always be perfectly successful. Today, old processes still exist, however there are modern products. To achieve a flawless varnish, you must know and respect the technical aspects of the product.

Products needed to varnish guitar

There are a number of clear lacquers that can achieve results that can be described as decent or superb.

It is of course preferable not to aim for economy, for such a small quantity of surface to be varnished and for a precious instrument, which we want to renovate or make last over time.

Without detour I advise you to use a professional product is a wise choice for those who want an easy application with good results, and without unpleasant surprises.

Acrylic varnishes

Thickness: 20-25 µm per dry layer / Brush and gun application

For those who prefer ecological and non-harmful products, to work quietly in their apartment, without the smell of solvent, then the first choice is to varnish a guitar with a water-based acrylic varnish. In the field of wood, this type of varnish is the most common. A guitar varnish in hydro acrylic formula is resistant, shiny, and light. It will harden little by little over the days and weeks, however it remains permanently flexible and not brittle. There is also a water-based polyurethane varnish which allows you to achieve a higher level of resistance: it is therefore a 2-component varnish which hardens by polymerization.

– Glossy or matte acrylic varnish Aquamin and Aquacel

– two-component glossy acrylic varnishvernis acrylique brillant bi-composant

Epoxy resins for impregnation or glazing

Epoxy hydro impregnating resin/varnish

Thickness: 25µm per dry coat / Brush application

Here again these are odorless products which can be handled in the workshop without any particular protection.

On raw wood, it is possible to impregnate it with a two-component water-based epoxy resin (Resoltech 1010) which can also be used as a very hard glossy varnish.

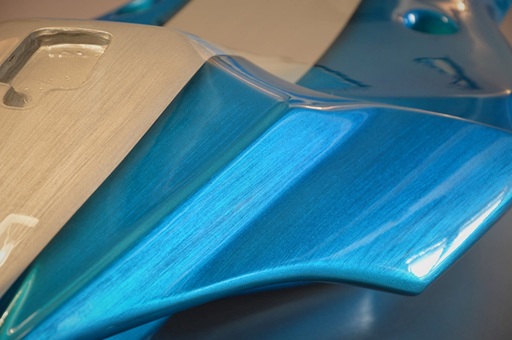

If one is looking for a glaze, with a deep wet effect, then the best product to achieve a significant thickness is resoltech’s 4000 epoxy resin varnish, which can create a huge thickness of up to 2 millimeters in a single coat, shiny and thick like a window. The epoxy resin is applied by pouring and it spreads itself because it is self-leveling. This glaze is probably not suitable for an acoustic guitar, it is more suitable for an electric guitar

Thickness: 1 to 3 mm per dry layer

Nitrocellulose varnishes

Thickness: 15µm per dry layer / Brush and gun application

Nitrocellulose varnishes for guitars are glossy solvent-based varnishes developed a long time ago, at the beginning of the 20th century. At the time, they wore the first automobiles. Unfortunately these were not varnishes that could resist UV or hydrocarbons. On the other hand, these are varnishes that are easy to use and dry by evaporating. They have long been used and favored by guitar manufacturers, for economic reasons and also because according to many musicians, this type of thin and flexible varnish offers the best natural properties of resonance and propagation of sound waves when applied. on guitar woods.

I invite you to discover our Nitrocellulose guitar varnish

The advantages of Nitro are simple application, no hardener, almost perfect tension, comfortable thickness and touch-ups are easy since the new varnish merges with the old one.

But it is also a defect, a finish which reacts to the slightest solvent is a capricious finish, traces or halos from contact with certain protective foams, complicated cleaning which can ruin the finish if the wrong product is used.

This is a varnish that will take months to harden completely. In short, in my opinion, it is not easy to choose such a finicky varnish, to cover an instrument that is handled often every day.

Polyurethane varnishes

Thickness: 25µm per dry layer / Brush and gun application

“A P.U. polish. is insensitive to solvents, extremely durable to handle, it is complicated to implement but frankly now with the products offered to us I do not see the point of doing without it…”

They are called 2C varnishes because they have 2 components and they harden by chemical polymerization rather than by evaporation and drying. These are solvent-based acrylic polyurethane varnishes for professional use (They are harmful and must be applied in a paint booth or with sufficient air extraction, and the applicator must wear a respiratory mask). They reach unrivaled levels of resistance in terms of hardness. They ensure and guarantee a very high level of resistance to abrasion, scratches, friction and even chemicals. This does not go without maintaining a natural flexibility which prevents them from becoming brittle and shattering over the years.

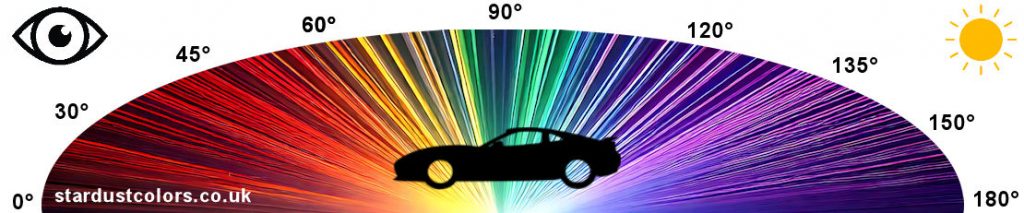

This type of varnish surpasses all other types of acrylic or cellulosic varnish in its shine. They easily show degrees of specular shine beyond 90°.

High gloss “wet look” finishes are ideal for “high polish” techniques.

My selection:

♦ UHS830 glossy varnish kit

♦ UHS830 two-component glossy aerosol varnish version

♦ WetSpeed polish kit – quick versionkit de vernis WetSpeed – version rapide

Finally, since we are talking about varnishes using bodywork, I could not end this chapter without presenting to you the best option for extreme finesse, maximum hardness and record shine, it is the ceramic varnish version X, and which dries completely in 45 minutes. Its finesse would not be unrelated to the quality of the sound obtained…

The 6 steps to varnish your guitar

Step 1 ► Prepare the Guitar Stand

If you are working on raw wood:

You will need to dry sand with P320 grit and a sanding block. Once sanding is complete, expel the dust with a blow gun and compressed air. If you do not have an air compressor at your disposal, then use a brush and rub vigorously to remove all micro dust and sanding residue.

On the body of your guitar with varnished wood:

Perform surface sanding with P500 abrasive grain.

I strongly advise against stripping (chemically) or even completely removing the coating by abrasion, except in the case where it is really in very poor condition and is peeling off.

Once your varnish is sanded, use a little rubbing alcohol to degrease the surface with a clean cloth to remove sanding residue and also to degrease.

Step 2 ► Impregnate the wood

This step does not concern you if you are working on the varnished or painted guitar, that is to say with an old base sanded, degreased and dusted.

Bare wood is porous and absorbent, and as a result you need to block this bottom before you can properly varnish it.

If you apply a varnish directly to the wood, some of it will be absorbed, and irregularities and micro-bubbles will appear on the surface.

So apply a professional acrylic varnish or impregnating resin to the wood in 2 or 3 coats. Observe sufficient time between each coat to allow the varnish to penetrate into the wood and allow the water to partially evaporate.

The impregnation resin is a 2-component product, based on epoxy resin in a water emulsion. It is a product that will penetrate, block and harden the base.

I recommend the 1010 Resoltech impregnation resin that we offer.

It mixes with its hardener at a ratio of 1:1.

This type of water-based epoxy resin can be used both as an impregnation to prepare the wood of the guitar, but also as a glossy finishing varnish. Being a 2-component epoxy-based product, it is notably more resistant than a simple acrylic varnish.

Allow 12, 24 to 48 hours to dry thoroughly, depending on the number of coats you have applied for impregnation

Step 3 ► Sand

This step allows you to obtain a truly smooth and perfectly flat surface. The first layers of impregnating varnish made it possible to fill the crevices but also to create a leveling layer. This is the foundation to be able to apply the finishing varnish.

Sand superficially with P500* dry paper, without crossing!

Be careful not to sand too much on the edges and corners of the guitar parts so as not to cross over your impregnating varnish.

*It is not necessary or recommended to use a sanding sheet grit finer than P500. You don’t have to worry about visible scratches in your polish, whatever it may be. The P500 grain is sufficiently fine and it also creates maximum adhesion in which your varnish will be able to anchor itself.

Once the surface is sanded, I advise you to run your clean, dry hand over the surface of the varnished and sanded wood. Feel the texture with your fingers, and look for the slightest imperfection, look for areas that are not completely smooth and soft, or small grains remaining. Once this sanding is finished, remove all dust with a damp cloth, or use the compressed air blower.

Step 4 ► Apply varnish

The surface is clean, sanded, dry, degreased, and therefore you will be able to apply your varnish!

Brush, roller, airbrush or spray gun?

The best method of varnishing is with a paint gun.

You won’t be able to varnish with an airbrush, because it’s too small a tool for a guitar. Varnishing requires a certain flow of product to obtain a shiny and homogeneous layer.

If you paint with a brush or roller, then make sure to apply as thickly as possible to allow the varnish to self-smooth. For example, you can pour the varnish onto the surface of the guitar, and distribute it with the brush or roller.

The varnish is always applied in 2 coats: take care to wait until the first coat is sticky before applying the 2nd coat.

With the spray gun, we do not touch the surface because we spray and atomize the varnish from a distance of approximately 15 cm. This is ideal for obtaining a beautiful, shiny lacquered surface.

Applying acrylic varnish with a spray gun to a guitar

Use a pneumatic gun with a 1.4mm nozzle

You can dilute the varnish with up to 5% water.

Apply a thick coat, then allow 30 minutes to dry before applying a 2nd coat.

Applying a polyurethane varnish with a spray gun to a guitar

Start by preparing the mixture with a weighing scale.

Respect the mixing ratio between varnish and hardener as precisely as possible. Take careful note of the instructions on the product technical sheet and only mix the quantity necessary, as your mixture has a very limited shelf life (generally between 30 minutes and an hour)

You can add thinner up to 20%, only if necessary, for example if you are using a mini gun

Apply a medium coat, then allow 8-10 minutes for solvents to evaporate.

Apply a second and final coat (the final coat), and make sure it is thick enough to spread well over the surface to give a high-gloss wet look.

How to get a perfectly shiny spray varnish?

If you are varnishing a guitar, your goal is to obtain an ultra-glossy, thick, mirror-reflective varnish. However, it is also possible to obtain defects of lack or excess, which manifest concretely by drips or by a lack of shine.

Of course external conditions such as humidity, cold or heat can contribute to creating a lackluster varnish, however it is above all the quality of the varnish and the action of applying the varnish to the guitar that makes the difference.

The whole secret of successful varnishing lies in the “amount of varnish deposited on the surface” of the guitar: this amount of varnish results from the distance of the paint gun, the speed of movement and the angle of the gun. So keep your gun perpendicular, at a distance of 10 to 15 cm, and move your gun regularly without going too fast or too slowly.

Apply more layers

I do not recommend that you apply more than 2 coats, both in the case of an acrylic varnish and in the case of a solvent varnish. I mean 2 coats per session: applying 3 or 4 coats in one go will certainly produce a thicker coat, but will increase the risk of running, and will inevitably reduce the level of shine. This is called “burying” the varnish.

You will be able to obtain an ultra shiny and deep surface, by practicing repeated varnishing sessions, always allowing 24 hours of drying, by carrying out fine sanding, for example with P800 paper.

The best conditions for applying varnish to a guitar

I advise you to choose a day with a mild or warm temperature (Minimum 18°C), and a fairly low humidity level. If you use a polyurethane varnish and use it outdoors, be careful of dust by applying the varnish on a windless day and in a clean place. You can first fix the dust on the floor by vacuuming then with light watering. Of course, we are never safe from a small defect, a small particle, an insect which lands on the wet varnish, but it is not very serious, because we will see how to polish on a guitar varnish.

Step 5 ► Dry

Let the varnish dry and harden in a dry and gentle environment (24 hours at room temperature).

The drying time depends on the ambient temperature and also on the thickness of the type of varnish.

It is important to read the drying times detailed on the technical sheet. Some polyurethane varnishes dry thoroughly in 24 hours, and as an exception certain polyurethane ceramic varnishes dry thoroughly in 45 minutes.

In general It is possible to start handling and transporting the guitar after a few hours.

For assembly and commissioning of the guitar, I advise you to be patient and allow additional core hardening.

Acrylic or solvent-based varnishes naturally harden more and more during the first 7 days after application. It is normal that one can be marked with the nail if you press hard on the varnish.

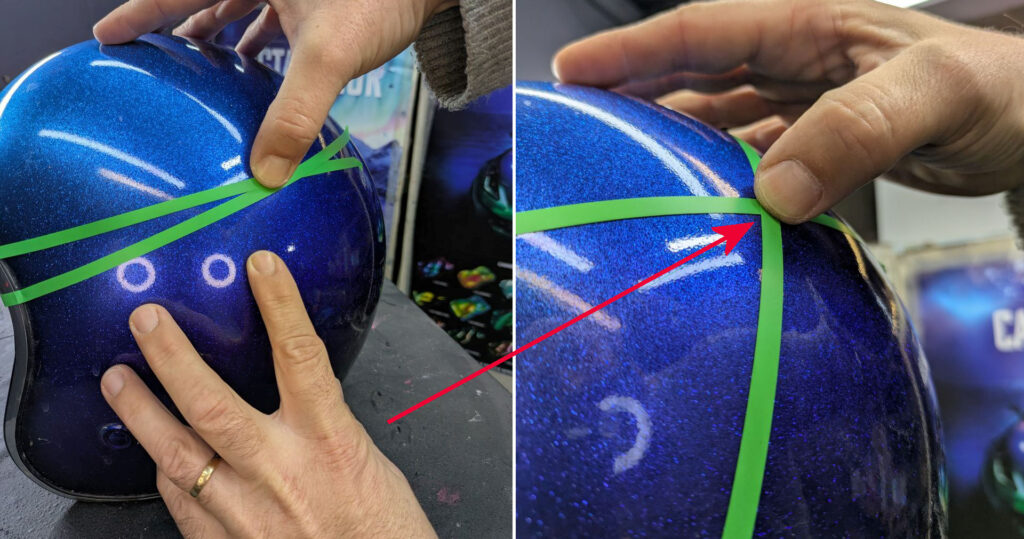

Step 6 ► Polish

“Mirror polish” polishing is an optional step and can be carried out from 24 hours after the application of a 2-component polyurethane varnish.

It helps perfect the shine and remove certain micro defects, such as orange peel or a grain of dust.

I wrote a complete article on polishing techniques in automobile bodywork. In truth, these are exactly the same tools, the same products and the same techniques that we will use on a guitar.

Polishing is carried out with a polisher, there are even mini pneumatic polishers (link) with 75mm discs)

Defects are removed with P1500 or P2000 water abrasive discs. The shine of the varnish disappears momentarily during the first stages. Then, we must carry out the polishing with 2000 and 4000 discs and a polishing compound. The speed of rotation allows a rise in temperature which will modify the surface condition of the varnish and give it a very high shine.

VARNISH AND SOUND

If you ask guitarists and audiophiles, the choice of varnish is very important. Among the latter, some claim that it is a secret that influences the quality of the guitar’s sound.

It is true that in terms of acoustics, the type and thickness of the varnish is important. However, have the Stradivarius benefited from cutting-edge varnish for hundreds of years? The choice wasn’t as important back then as it is today!

According to Stardust, it is important that the varnish is thin, that is to say that in its “dry” state, its thickness should not exceed 50µm, or 5 times the diameter of a hair. The flexibility and hardness of the varnish (the latter will increase over time) are two important parameters.

Add coloring to the guitar varnish

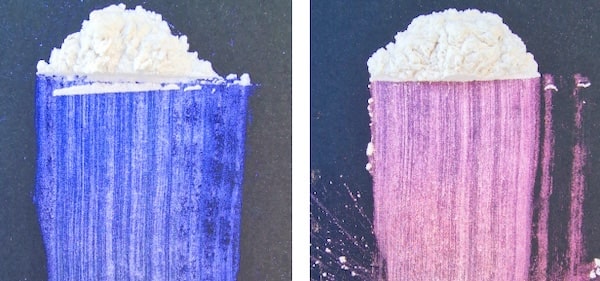

To give color, there are pigments and dyes. To create transparent coloring in a varnish, and allow tinting without masking the texture of the background, then only transparent dyes must be used.

These are concentrated soluble tints which are added to the varnish at around 5 to 7% of the total weight. These concentrated inks are called “Candy”

There are Candy inks concentrated in solvent phases

there are Candy inks concentrated in aqueous phase

There are also ultra-fine dry pearl pigments, which can be added to varnishes to add a slight pearly reflection to the finish.

How to apply paint to a guitar?

Aware of the importance of forests for the preservation of biodiversity and the protection of animal and insect species, StardustColors has launched a bold initiative: planting a tree for each order placed**.

Aware of the importance of forests for the preservation of biodiversity and the protection of animal and insect species, StardustColors has launched a bold initiative: planting a tree for each order placed**.