Hikari Toys for Soft PVC – Interview StardustColors

For two years now StardustColors has been offering the HIKARI Toys for Soft PVC range of paints specially designed for soft vinyl toys.

Today we welcome Stéphane, a user of the range since the start of its marketing, to tell us about his hobby: sofubi painting.

> Hello Stéphane and welcome. Before getting to the heart of the matter, can you introduce yourself in a few words?

Hello to the whole Stardust team! So Stéphane, I have been a sofubi collector since 2009. In 2016 I decided to take the plunge and start painting this type of toy to give an extra dimension to my hobby. I also have an Instagram account (https://instagram.com/_thechogokinjawa_) where I present, among other things, my projects trying as much as possible to present their WIP (Work In Progress) to show the different stages of painting until the final result.

> But what exactly is sofubi?

Sofubi is the phonetic contraction of the Japanese “sofuto biniru” which refers to PVC toys. In the hobby we use this word interchangeably or sofvi, the English contraction of “soft vinyl”… it’s quicker than talking about soft vinyl toys… and a little more flattering too (laughs).

> How long have these types of toys been around and where do they come from?

Originally these were Japanese toys which began to be produced after the Second World War for the American market. But from the 1960s, sofubi took on real importance in Japan with the marketing of toys based on films and TV series around Godzilla or Ultraman. Very quickly sofubi developed, mainly on the themes of monsters (kaiju), robots or creatures of traditional Japanese folklore (Yokai). At the end of the 90s, sofubi took on a new dimension when street wear stores such as Bounty Hunter decided to start selling soft vinyl characters. Since then, this phenomenon has continued to grow, sparking vocations beyond the street culture community and has even spread to other Asian countries (China, Hong Kong, Taiwan, Thailand). ) or the United States. Today the themes in sofubi are almost endless because it is an environment where everyone can give free rein to their imagination when it comes to creating a figurine. From very gory to very kawaii (which means cute in Japanese) there is something for everyone!

Sofubi offers a very wide variety of themes, sizes and colors!

> But what ultimately differentiates the sofubi from other toys?

Compared to toys that can be found on the market, I would say that a sofubi can appear extremely simplistic and sometimes give the impression of being one of those cheap toys that you see at fairgrounds.

It’s true: a sofubi is made of hollow plastic, is made up of few parts (this can range from two to at most ten) and is not very articulated (it is often the bare minimum: head, arms and legs).

And this is for good reason: each sofubi is made by hand using artisanal techniques that have not changed since the very beginning. We are therefore very far from mass production and in the end the number of copies of a sofubi will not exceed a few hundred (or even thousands for the most fashionable models) over several years.

On a sofubi the effort is focused on two aspects. First of all, the design: some artists produce phenomenal work of sculpture with incredible attention to detail. And then the painting: each piece being painted by hand, the sofubi leaves the door open to all possible and imaginable shades.

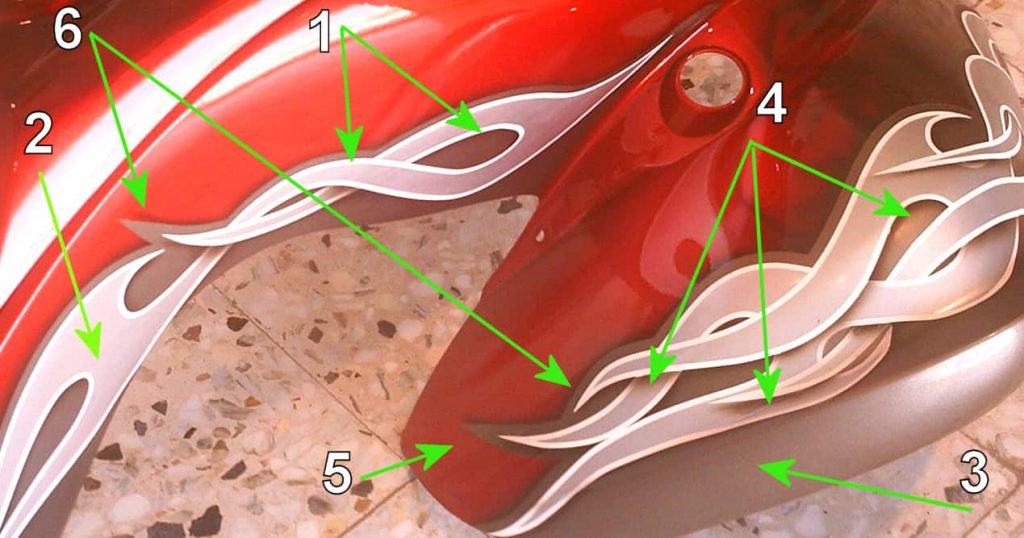

Anatomy of a sofubi

> Thank you for all these details and this transition to the theme of painting! What do you think is the main difficulty in painting a sofubi?

The main difficulty in painting a sofubi? I would definitely say it’s finding the right paint! (laughs)

More seriously, I think that before starting to paint any object (a plastic model, a resin kit or a sofubi), you have to “get to know it” to determine which paint will be the one. more suitable.

The case of sofubi is quite particular in the sense that it is the way in which it is designed which will dictate the choice of paint to use.

In fact, to paint a sofubi you have to start by dismantling it. To do this, we will soften the vinyl by heating it. So far so good.

Once the different parts have been painted, everything must be reassembled.

And this is where things get complicated: the painted parts will have to be softened again by heating them to fit them into each other.

We therefore need a paint that is both flexible to withstand the pressure that we will exert on the parts during reassembly and resistant to the friction that can occur in certain places of the sofubi (which I remind you is not necessarily perfect because it is made in an artisanal way).

The optimal solution therefore lies in a vinyl paint which combines these two properties, because it has the particularity of creating a chemical bond with the vinyl substrate of the sofubi.

Before StardustColors launched its HIKARI Toys for Soft PVC range, there was none of this in France or even Europe. The arrival of your paint was a real game-changer!

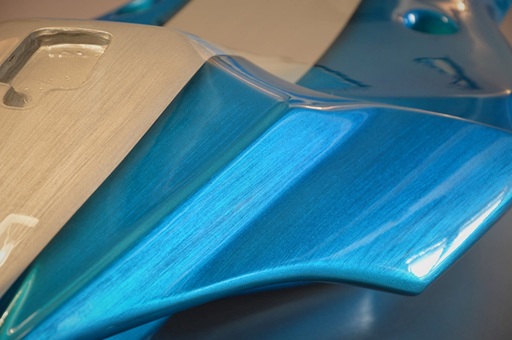

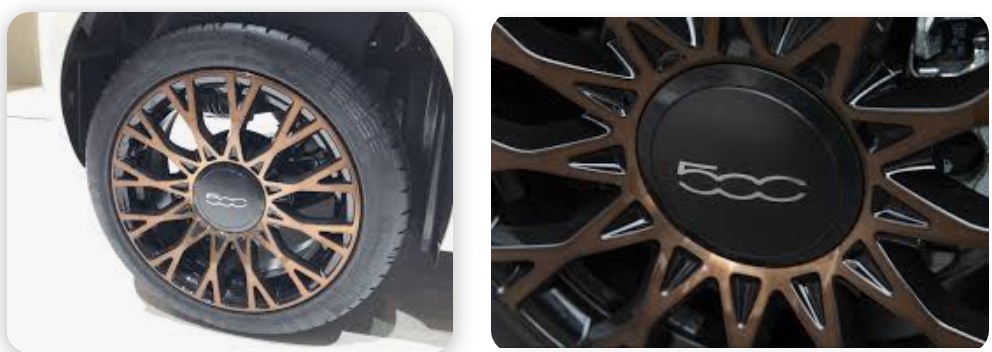

Hikari Toys paint with matte varnish from the Graphic range

> But then what did you do before HIKARI Toys for Soft PVC paints?

In principle, you can paint the sofubi with almost any type of paint other than vinyl paint: acrylic (water or alcohol base), solvent-based or enameled (enamel).

But they are not really suitable because none has the capacity to create the chemical bond with the vinyl substrate that I spoke to you about previously.

As for me, I used solvent-based paints for their quick drying and relatively good resistance to friction. I could quickly handle the part which was very quickly dry to the touch and continue working on it.

On the other hand, at the time of reassembly, if the paint is not suitable it can quickly turn into a nightmare: the paint can crack (or even jump), poorly resist the heat (resulting in fingerprints on the part) …I can’t count the number of times I’ve ruined hours of work in just a few seconds. I won’t hide from you that this type of mishap, which happened quite regularly, was extremely frustrating and even discouraging.

> Very good, but StardustColors is not the only company producing vinyl paints for sofubi. So why not use other brands?

Because the other manufacturers are either in Asia or in North America and in the best case scenario I could have bought the paint in concentrated form but not the thinner, due to international air transport regulations.

And I’m not going to teach you this: each paint has its appropriate thinner. Painting is above all chemistry! (laughs).

In short, without the thinner specially designed for paint, it is impossible to extract its full potential, especially knowing the rather particular properties of vinyl paint…but here I am starting to get into the technical details.

> That’s perfect, so let’s talk technical now! First of all, what materials do you need to paint sofubi?

Basically, a sofubi is painted with an airbrush because vinyl paint is not particularly suitable for painting with a brush.

You will need an airbrush that is absolutely equipped with Teflon (PTFE) seals to resist solvents….otherwise I won’t give you much of your equipment after a few uses. And of course add a compressor to it.

I advise you to choose airbrush brands whose reputation is well established: Japanese (Iwata, Wave, GSI-Creos) or German (Harder & Steenbeck). They are all very good, although I must admit that I have a slight preference for Japanese airbrushes.

I suggest you first opt for a versatile airbrush with a 0.3 mm nozzle. It will allow you to do just about anything you want. And if you decide to go further in detail work, then I advise you to add a 0.15 mm or 0.18 mm airbrush to your painting equipment.

Of course, using an airbrush with vinyl paints requires taking precautions for your health. So cartridge mask and paint booth with extraction to the outside are mandatory!

Finally, when it comes to cleaning my equipment, I use acetone or cellulose thinner and it does the job very well.

At the top the Super Airbrush Advance (0.3 mm) from Wave and at the bottom the PS-771 (0.18 mm) from GSI-CREOS

> Before starting to paint a sofubi, should we take any special measures?

Firstly, I degrease the toy because there are often residues of mold release products. Getting rid of it will help the paint stick.

For a plastic model or a resin kit I generally use soap or dishwashing liquid, but for a sofubi it is the paint thinner that will be used for cleaning.

Not only will this degrease the part but it also prepares the vinyl to be painted. Cleaning with thinner creates a temporary reaction in the vinyl (it will feel sticky to the touch) and this will promote the famous chemical bond with the paint.

As for me, I clean the part by rubbing it with a cloth soaked in thinner then I immediately apply the first sprays of paint to retain all the benefits of this cleaning.

> Now let’s talk about using HIKARI Toys for Soft PVC paints. What advice could you give to someone who is going to use them for the first time?

I have advice that can be summed up in just one word: dilution.

I consider this to be the essential thing to have in mind, not only when painting with an airbrush but even more so with a vinyl paint like HIKARI.

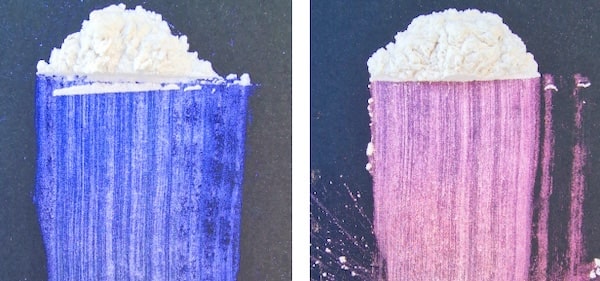

When it is not diluted enough, a vinyl paint will quickly let you know because it has the particularity of producing a “cobweb” effect. You will end up with filaments on the object when spraying the paint and I can tell you, the first time it feels funny! Increase the dilution and the problem will disappear instantly.

Vinyl paint is also sensitive to ambient temperature. Be extremely vigilant about this, otherwise you risk exposing yourself to another phenomenon: overspray.

Concretely, when spraying the paint you will notice around the painted area the appearance of a white powdery layer, often in the corners of the room. This is because the paint is already almost dry when it comes into contact with the part. If you have not changed the pressure at which you are working then this means that your dilution is not sufficient in relation to the temperature.

In short: for the same paint application, the dilution may vary depending on the season.

And to be really calm, I advise you to add HIKARI “retard” to your diluted paint. As its name suggests, this product will delay the drying of the paint and will therefore further limit the risks of overspray.

If, despite all this, you still have a slight residual overspray, I’ll give you a little tip: a veil of pure HIKARI “retard” quickly sprayed on the bleached area will solve the problem.

> Thanks a lot for the clarifications ! In the end, what dilution would you recommend?

Personally I work with a dilution between 1:1.5 and 1:2 by volume (the first number being the volume of paint and the second that of the thinner) with a pressure of 20 psi at my compressor.

If I ever have to paint small details or want to work transparently then I increase the dilution. This can go up to 1:5 or even 1:7 and I adapt the pressure accordingly.

As I always prepare bottles of previously diluted paint, another little tip: by default I always add between 2% and 3% by volume of HIKARI “retarder”. This is the price of a certain tranquility! (laughs)

> Before ending this interview, do you have a few last little secrets to share with us regarding sofubi painting?

With pleasure! First of all, the first will concern painting with the HIKARI Candy range on transparent vinyl sofubi.

Even if the dilution is appropriate, it is possible that at the transitions between the different Candy colors you will have some sort of tarnishing.

To remove this effect, I spray a fine veil of pure Hikari “retarder”.

My second tip will concern the final appearance that you want to give to your sofubi. Basically, HIKARI Toys for Soft PVC paints have a satin finish. To give your sofubi a matte appearance, apply a layer of Medium HIKARI and that’s it!

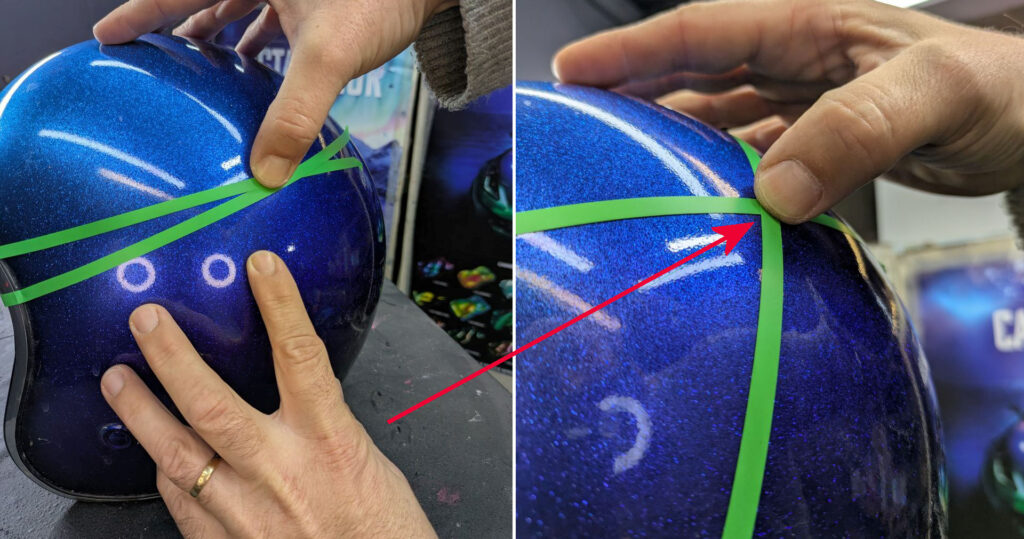

Finally, two tips for the sofubi reassembly phase.

First of all: patience! Even if HIKARI Toys for Soft PVC paints dry very quickly to the touch (a few minutes), wait at least 24 hours for them to be completely dry before reassembling your sofubi.

And then: moderation! HIKARI Toys for Soft PVC paints are certainly flexible and resistant, but they are no less heat-sensitive. So heating the room to too high a temperature risks having the opposite effect to that sought: certainly you will very quickly soften the painted vinyl but you also risk starting to melt the paint and damage it when you go. re-fit the parts.

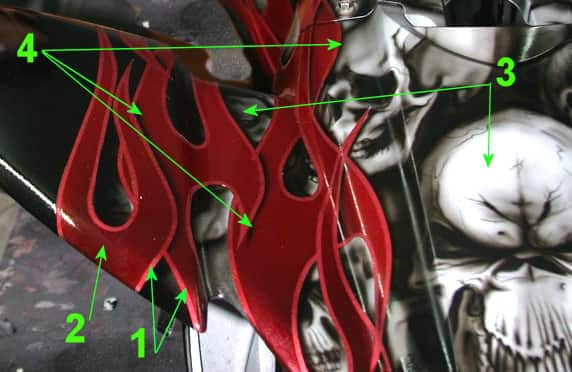

Sofubi made with HIKARI Toys for Soft PVC paints

> Thank you Stéphane for all this information! I think readers of the blog are now ready if they want to get started with sofubi painting!

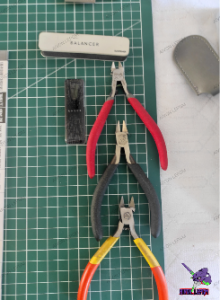

For assembly, a pair of precision tweezers, a glass file, do the job from the start. You should avoid low-end equipment anyway!

For assembly, a pair of precision tweezers, a glass file, do the job from the start. You should avoid low-end equipment anyway!