Chameleons

Also called Flip flop, Beetle shell, Harlequin effects.

Also called Flip flop, Beetle shell, Harlequin effects.

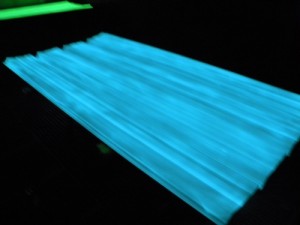

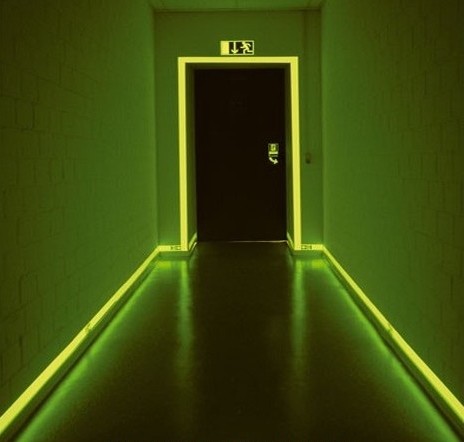

The famous Chameleons paints create an extraordinary and surprising visual effect by changing colour (double, triple or quadruple), as the observer moves around the painted object. Two main colours can always be noticed, while the secondary colours will show at the angles.

It’s the light reflection on the chameleon pearls that gives to the paints their multi-coloured changing effect.

That’s why it is important to always apply it over a black base coat, because black doesn’t interfere with light whereas chameleon pigments reflect light ( when applied over a white background, most chameleons are invisible). They are ideal to create your own custom paint, whether for car, motorcycle paint, or in the home. You will get a great chameleon paint that will amaze everybody.

StardustColors proposes a large choice of 16 chameleon colours, available in spray and in can, and divided up into three categories, as follows:

• Sparkle: Medium size pearl flakes. Transparent type

• Stardust: Very small size pearl flakes . Non transparent type

• Colorwave: Ultra-thin size pearl flakes. Transparent type

Special chameleon pigments:

• Liquid Crystal: Very small size pearl flakes. Non transparent type. Candy paint have been added to offer greater colour saturation and depth effect.

• Diamond: Large size pearl flakes. Ultra-transparent type. Top quality materials made with glass microparticles for high index of light reflection.

How to create unique and amazing colours ?

Some transparent chameleon pigments (and only those!), can be applied over any basecoat colour other than the usual black! You can spray over a blue, red, orange, white or even grey background, to get unique and unexpected combinations!

How to apply the chameleon paint ?

The painting technique is extremely easy. The first rule for painting chameleon is to apply the paint over a black background. The second one is to spray very thin passes. The more you add paint the more the chameleon will show and become coloured. If not enough paint is applied, the chameleon effect will not show properly.