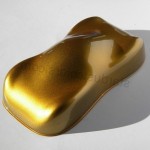

Chrome paint system – Industrial version

The StardustColors chrome effect paint is the best on the market : it produces a true mirror chrome effect.

The chrome paint effect is easy to apply using a spray gun over a gloss hard background.

The mirror layer is composed of aluminum flakes and is only a few micron in size once dry.

Yield: 4 to 5m²/L

For a quote and data sheet, contact us by email.

Different from the system on sale to the general public, the industrial chrome paint system provides an excellent level of adhesion between the coats (base/chrome/topcoat) and a shorter implementation time, for automatic paint lines The industrial system requires baking.

More details : Chrome paint

Chrome paint : what is it ?

This system consists of two products

CB7: For the undercoat and the topcoat

CHR : Chrome effect paint

The CB7 Base exists in 3 different kinds of packaging

1.65L Kit (1L CB7 + 150ml Hardener CCB7 + 500ml Thinner)

8.5L Kit (5L CB7 + 1L Hardener CCB7 + 2.5L Thinner)

33L Kit (20L CB7 + 3L Hardener CCB7 + 10L Thinner)

The chrome effect paint exists in 3 different kinds of packaging

– 1L

– 5L

– 21L

CB7 Topcoat

The CB7 Base will have a dual use: it will serve as a gloss and hard base to receive the chrome paint, and will also be used for the clear coat application.

This is a clear polyurethane topcoat that ensures adhesion with chrome paint without sanding. CB7 adheres directly to many plastics and metals.

Mixture: by weight, 100 parts of CB7 + 15 parts of Hardener CCB7 + 20-50 parts of Thinner

It is recommended to apply the CB7 Base over a black background for best results.

The CB7 Base is applied in 1 or 2 thin passes.

After 10 minutes of desolvation, proceed with baking

Recommended thickness: 25µm dry

Baking* of the CB7 Base:

1h at 100°C / 2-3h at 80°C / 3-5h at 60°C and minimum 3-7 days at room temperature > 20°C

*Ventilated baking

These recommendations are valid to get the best results.

Baking time can be shortened. Incomplete drying will produce a less perfect mirror effect.

Single-component ready-to-use product – Alcohol-based

The CB7 Base should be covered with the Chrome paint immediately after its temperature has dropped below 40°C

The chrome paint is applied in very thin repeated passes, until the surface is covered.

Allow a 20 seconds interval between each coat at 20°C

Allow a 20 seconds interval between each coat at 20°C

The chrome paint is immediately dry to the touch.

In order to facilitate the topcoat application without losing the mirror effect, it is recommended to bake the paint or use a flame treatment

5min at 100°C / 10min at 80°C / 20min at 60°C and minimum 48h at 20°C

Clear coat application is carried out with CB7, with prior very thin passes in order to fix the surface of the chrome paint without wetting it.

Then apply 1 or 2 passes