The midcoat in Custom paint

Transparent base, binder, resin, interlayer, midcoat, medium… these are just some of the many terms used to describe this product, which has as many names as it has uses.

In this article, we will clarify everything related to transparent midcoat base and present all the possible uses that this transparent binder can offer painters.

What is a transparent interlayer base?

It is a product specific to the field of custom painting.

In the field of car bodywork, it is used solely for mixing paints: car body painters call it the ‘binder’ or “resin” or sometimes, according to the Anglicism, ‘Binder’.

The binder is simply the base of the paint. It is a mixture of acrylic (or polyester or nitro) polymers in a solvent or water phase, which binds the pigments, allows adhesion, and provides strength, flexibility and texture.

All major automotive paint brands offer a midcoat binder in their colour system. The car body painter adds all the concentrated opaque or transparent, pearlescent or metallic pigment pastes to mix their colour codes.

The appearance and characteristics of a binder

The midcoat or binder is a liquid that varies in thickness and has a cloudy or whitish appearance. The binder is matt and transparent once it has been applied and dried.

The binder is rarely as transparent as a varnish, but it is sufficiently transparent to be completely colourless and invisible. Once applied and dried, the thickness of a transparent midcoat binder is only about 15 microns per coat.

Midcoat binder is always single-component (1C), as it is a base coat for varnish.

It can be supplied pure, to be diluted (50 to 100%), or supplied already diluted, ready for use with an airbrush.

There are different types of midcoat

-HS: high solid content, HS binder is thicker, strong and resistant to pigment load, ideal for colour formulations, protection, mixing glitter, candy and iridescent effects

-MS: Medium Solid, the MS binder is thin and ideal for pearlescent and metallic effects

-Crystal: the Crystal binder is translucent like varnish and is a special type

-Hydro: the water-based Hydro binder is used to comply with the European standard on VOC limitations.

Fields of application

In the field of creative leisure and plastic arts, it is used as a medium. These are often water-based acrylic binders.

In the world of custom painting, midcoat is used for several different purposes, with a paint spray gun or an airbrush. Here are the different possible uses and advantages:

1/ Mixing pearlescent pigments and Candy

Rather than adding dry pearlescent pigments to the varnish, it is preferable to add them to a transparent matt base coat.

► Advantages: thin application, quick drying, and optimal placement of pearlescent pigments, which lie flatter than in a thick varnish.

This also prevents the pearlescent particles from moving during drying and avoids dripping when applying multiple coats.

With a midcoat binder, you can apply as many coats as you want at once without the risk of dripping.

2/ Fixing and protecting decorations

When creating a painted decoration with overlapping layers and different colour areas, the masking and painting work can take several days.

► Advantages: The transparent intermediate coat allows you to lightly sand the surface at the start of the day to ensure the new layers adhere properly without damaging the decoration.

This is particularly useful when creating freehand designs with an airbrush. The transparent intermediate coat creates a very thin but effective protection against stains and scratches until the next design session.

For those who use water-based airbrush paints, there are transparent airbrush binders available in small bottles, ready to use.

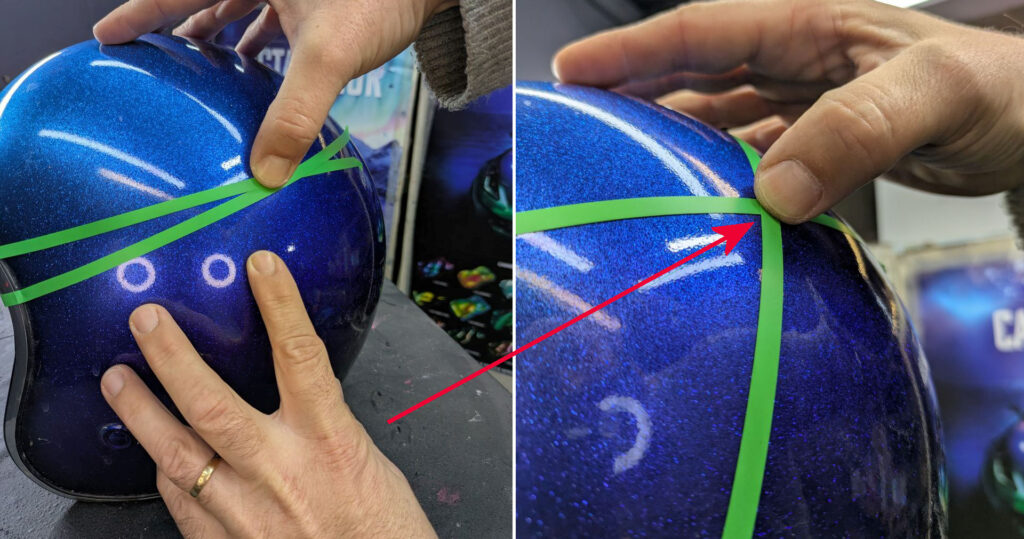

3/ Isolate adhesive masking

When two adhesive PVC lines cross, a small tunnel can form at the intersection of these lines or colours can seep through. When there are many lines and adhesive masking, it becomes difficult to control everything, and this is where the transparent midcoat binder can be used to create an ultra-thin, invisible insulating layer to prevent any risk of leakage.

4/ Mixing and creating colours

If you want to create your own colours by mixing concentrated shades, pearlescent or aluminium pigments, or even fluorescent pigments or phosphorescent, you will need HS binder.

The binder can be loaded with 3 or 4% pearlescent pigments and 5 to 25% colourants.

Using midcoat binder to create candy paint

Custom painters do not all agree that a single-component transparent intermediate coat is as transparent as a clear coat when painting with candy paint.

While it is possible to apply several coats of Candy clear coat to motorcycle parts, it is often difficult or impossible to apply repeated coats of clear coat to vertical surfaces such as those on a car without causing runs or even marbling defects.

In such cases, a midcoat binder is mainly used, which allows multiple coats to be applied to achieve a very deep and dark Candy colour. Thanks to its immediate drying time, the pearlescent or Candy coats set immediately and form a perfect film.

Some claim that the transparency is the same, while others say they perceive a slight difference in the level of transparency.

What interlayer binder cannot do!

This versatile product, essential for custom painters, has many advantages, but there are some things it cannot do:

❌ Levelling: Transparent interlayer binder cannot be used for levelling, as it is far too thin for this purpose. It is half the thickness of a conventional automotive varnish.

When you want to fill with a transparent material to level a surface, for example after applying polyester flakes, you need to use a very thick varnish such as Super UHS 6000 varnish.

❌ Blocking migration:

When covering soluble colours such as Candy colours with light colours, the solvents reactivate the Candy colours, which then bleed into the topcoat.

In such cases, a transparent midcoat base coat will not create a barrier against Candy migration. Candy can only be blocked by a sufficiently thick layer of two-component varnish.